| Model | AKZ1610 | AKZ1625 | |

| Max. Cutting size | 1600*1000mm | 1600*2500 | |

| Multifunction Tool Head | Oscillating straight knife/Round knife/pneumatic knife/identification roller/ marker pen holder/puching hole device/V-groove cut tool/CCD camera/tangential knief/ drilling tool/projector/etc. | ||

| Security Device | High sensitive infrared induction | ||

| Cutting speed | Max. 1200mm/s (can be set up according to different materials) | ||

| Movement speed | Maximum 1500mm/s | ||

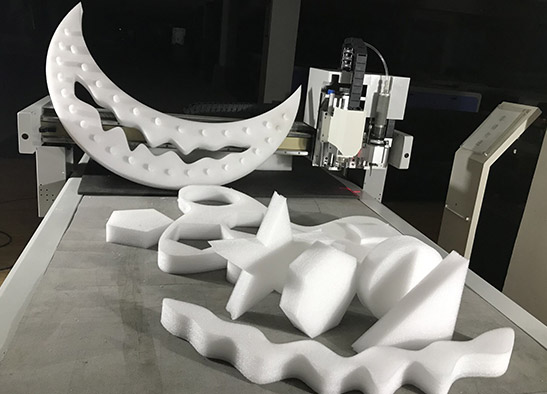

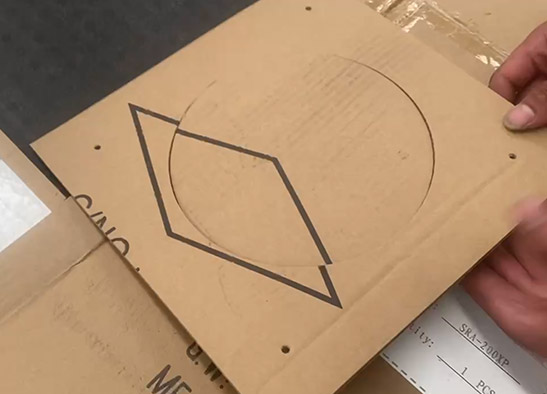

| Cutting material | Corrugated paper, PVC expansion sheet, kt sheet, thick foam, gray board, paperboard, car sticker, adhesive Sticker, etc. | ||

| Cutting thickness | Maximum 20mm (set according to different materials and tools) | ||

| Material fixing method | High power vacuum absorption with felt | ||

| Repeated positioning accuracy | ±0.05mm | ||

| Mechanical Precision | Maximum 0.05mm | ||

| Drive system | Taiwan Delta servo motor, Taiwan PMI linear guide rails | ||

| Control system | Chinese Brand RD control system | ||

| Transmission | XY by rack and pinion, Z axis and rotary seat by ball screw | ||

| Data transmission method | USB port or Ethernet | ||

| Support file | DXF,PLT,AI,SVG,PDF,NC,DST,DSB, etc. | ||

| Operation environment | Temperature 0-40℃, Humidity 20%-80%RH | ||

| Voltage | 380V/220V/50Hz/60Hz | ||

Machine features

The automatic feeding oscillating knife cutting machine is equipped with a lifting feeding platform, which uses infrared light to sense the position of the material and adjust the platform to a suitable height.

The CNC vibrating knife has fast cutting speed, high precision and stable performance. Various tool heads can be installed to suit different materials.

It is equipped with a CCD camera, which quickly scans the entire processing area before cutting, then identifies the reference point, and positions the material to achieve precise cutting.

Optional

V-Groove Cut Tool

Identification Pressure Roller

Pneumatic Oscillating Tool

Round Knife Cutting Head

Punching Hole Tool

Rectification Roller Frame

Applications

Acctek's after-sales

1 to 3 years guarantee of the whole machine.

Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

Lifetime maintenance free of charge.

Our staff can be sent to your company to install or adjust if necessary.

technical support online whole life

Write a Review

Related Articles

1

Today, I will show you a "spindle and oscillating knife&pressure roller 3 in1 CNC cutting machine", it is a multifunctional cnc machine specially customized by customers. After the wood and acrylic are carved and cut, the carton is made by the oscillating knife&pressure roller.

2

Oscillating knife cutter machine can cut and engrave leather, all kinds of clothing flexible material. How to perform daily maintenance on the vibrating knife?

3

When choosing a vibrating knife cutting machine, the manufacturer must choose a formal manufacturer with technical strength, because in this way, the quality can be guaranteed when purchasing mechanical products.

4

The choice of oscillating Knife and laser machine should be based on the products you need to produce, each has its own advantages

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd