CNC oscillating knife cutting machine tool comprehensive guide

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

In this article, we’ll explore the main tools available for CNC oscillating knife cutting machine and the specific materials each tool can cut, to help you make the right choice of tool for your cutting requirements.

CNC oscillating knife cutting machines are highly versatile in the manufacturing industry, capable of cutting a wide variety of materials with precision. Unlike traditional cutting methods, oscillating knife cutters use a tool that moves rapidly up and down to slice through materials smoothly. To expand their functionality, these machines are equipped with a range of specialized tools designed to tackle different types of materials.

In this article, we’ll explore the main tools available for CNC oscillating knife cutting machines and the specific materials each tool can cut. Whether you’re looking to cut foam, textiles, cardboard, or complex composites, understanding these tools will help you maximize the efficiency and quality of your cuts. Start reading now to learn which tools will best meet your cutting requirements and how they can enhance your production capabilities.

Understanding CNC oscillating knife cutting machine tool

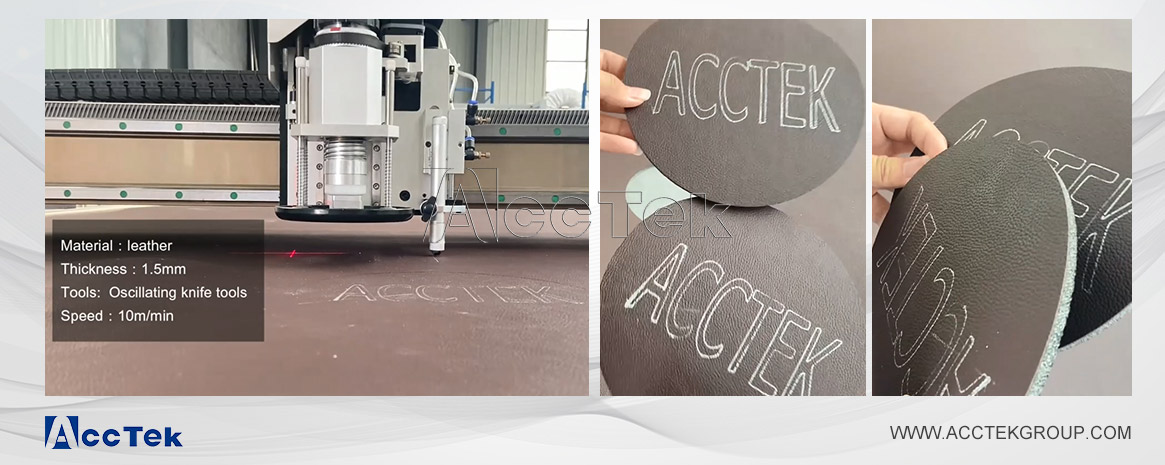

Oscillating Knife Tool: The oscillating knife tool is the cornerstone of any CNC oscillating knife cutting machine. This tool is designed to slice through soft to semi-rigid materials by moving in an up-and-down motion, allowing for precise cuts without causing fraying or damage to the material. This tool is ideal for cutting materials like foam, rubber, leather, cardboard, and textiles. These materials require the oscillating motion to achieve clean cuts without dragging or tearing, making this tool particularly useful for packaging, furniture manufacturing, and garment production.

Drag Knife Tool: The drag knife tool is similar to the oscillating knife but lacks the up-and-down motion. Instead, it “drags” along the surface of the material. This tool is ideal for materials that are thin and flexible, where high precision is essential. The drag knife tool is most effective on vinyl, films, fabrics, paper, and stickers. It’s widely used in signage and advertising for vinyl graphics, as well as in the fashion industry for fabric cutting. Because it does not oscillate, it is less likely to damage delicate materials, allowing for fine, detailed cuts.

Rotary Tool: The rotary tool is a motorized, small-diameter circular blade that can handle materials thicker or tougher than those cut by the oscillating knife. By rotating instead of oscillating, it can cut through fibrous or stacked materials with ease. Rotary tools are often used for multi-layer textiles, foam, carpet, fiberglass, and composite materials. This tool is ideal for industries that work with reinforced or layered materials.

Perforating Tool: The perforating tool creates a series of small cuts along a line, allowing the material to be easily torn or folded. This tool is valuable in packaging and printing industries where items need to be separated by the end user. The perforating tool works well with paper, cardboard, film, and flexible plastics. It is often used in ticket printing, packaging, and promotional materials. The perforated line makes it easy to tear or fold along a specified path without compromising the overall structure of the material.

Creasing Wheel: The creasing wheel is a specialized tool that adds creases along designated fold lines. This is especially useful in packaging and box-making, where precise folding lines are required for assembling products. The creasing wheel is best suited for corrugated cardboard, cartons, and paperboard. When used on materials that will later be folded, the creasing wheel ensures clean, uniform fold lines, preventing unsightly cracking or tearing along the folds. This tool is beneficial for producing high-quality packaging and display materials.

Pneumatic Tool: The pneumatic knife is a powerful, air-driven blade that uses pneumatic pressure to enhance its cutting force. This tool is especially effective for cutting thicker and denser materials that might otherwise be difficult for a standard oscillating or drag knife to cut. The pneumatic knife’s added power allows it to make deep, precise cuts on tough materials with ease. The pneumatic knife is suitable for cutting rubber, thick foam, leather, gaskets, and dense plastics.

Pen Tool: The pen tool allows CNC machines to mark or draw on the surface of the material before cutting. This is useful for adding guidelines, labels, or decorative elements to materials. The pen tool can mark paper, cardboard, fabrics, leather, and many other materials. This tool is valuable for prototyping, as well as for adding guidelines or marks on materials that will later be cut. In fashion and textile production, it can be used for marking patterns, while in packaging, it can add brand names or part numbers.

Choosing the right tool for your CNC oscillating knife cutting machine

Assess the Material: The first step in choosing the right tool is to evaluate the material you’ll be cutting. Different tools work better with certain materials, and selecting the appropriate one can prevent unnecessary wear on the machine and extend the lifespan of the tool.

Consider the Application Requirements: Each project has unique requirements that can affect tool selection. For example, you may need precise perforations, creased folds, or angled cuts to complete a specific task. Identifying these needs will help guide your choice.

Evaluate Production Volume and Speed Requirements: The production speed and volume you need can influence the ideal tool choice, as some tools are better suited for high-speed production than others.

Factor in Tool Durability and Maintenance: Some tools are more durable than others, depending on the material they cut and the type of motion they require. Understanding the wear characteristics of each tool can save on long-term maintenance and replacement costs.

Match the Tool to Your Industry Requirements: Lastly, consider industry-specific demands when selecting a tool. Each industry has its own standards for quality and production, and the right tool can help meet these requirements.

Choosing the right tool for your CNC oscillating knife cutting machine isn’t just about picking a blade—it’s about enhancing your machine’s performance, extending its lifespan, and ensuring your project’s success. By understanding the strengths of each tool and matching it to your material and application needs, you can maximize both productivity and quality. Whether you’re in packaging, textiles, automotive, or signage, the right tool will allow you to achieve professional-grade results with efficiency and precision.

AccTek CNC stands out as a well-known manufacturer of CNC oscillating knife cutting machines in China, offering a range of tools to meet diverse industry needs. With their commitment to quality and versatility, AccTek’s machines provide a variety of tool options that ensure precise, efficient cutting for an array of materials. For anyone in need of a versatile, reliable CNC oscillating knife cutting machine, AccTek CNC’s offerings are a smart and trusted investment.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd