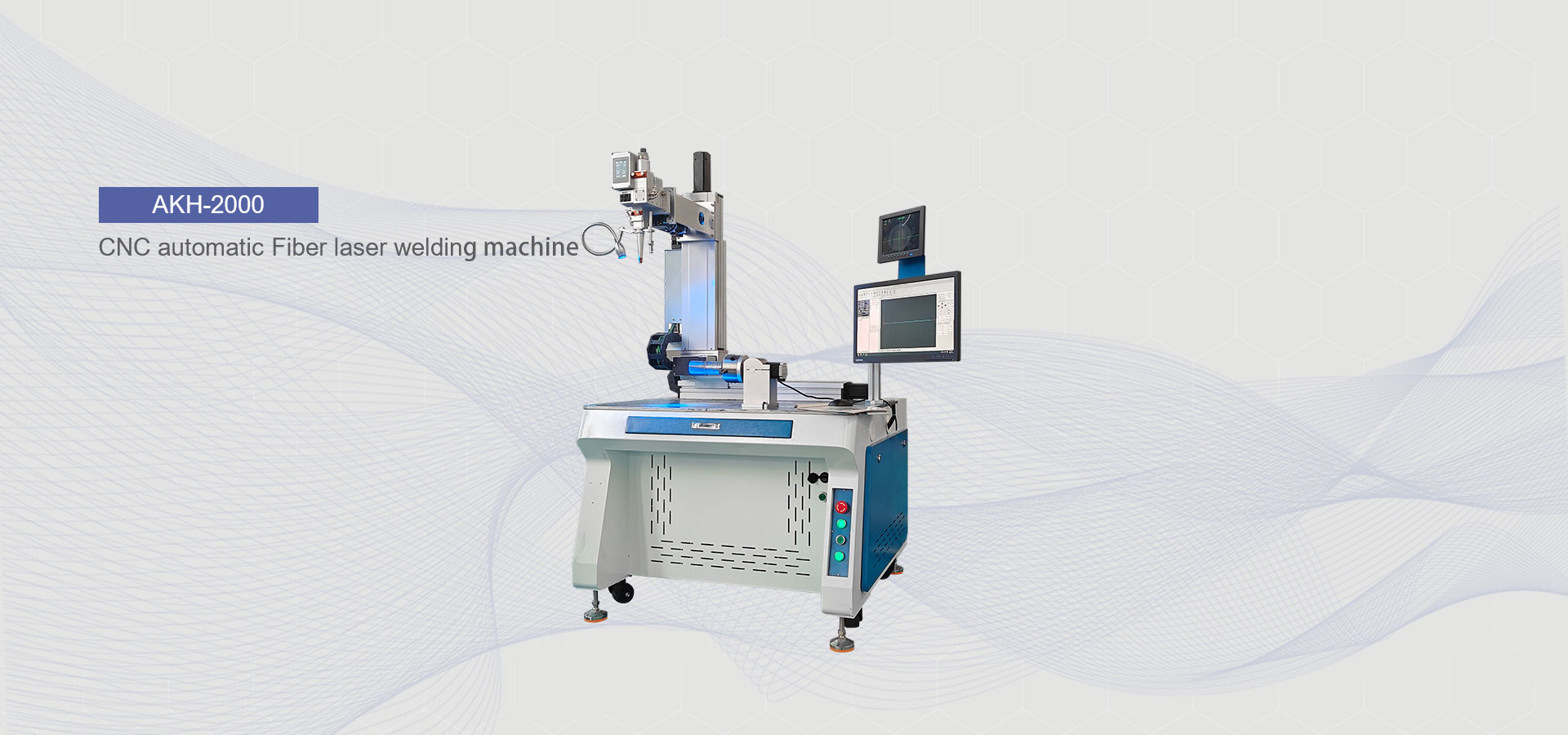

CNC Platform Automatic Laser Welding Machine

Model:

/

Category:

Laser Cleaner and Laser Welder

Brand:

ACCTEK

price:

$8200--$11500

Description:

The platform automatic laser welding machine excels in delivering high precision, efficiency, and versatility across a wide range of applications. Its automated capabilities, consistent weld quality, and ability to handle complex tasks make it a valuable asset in modern manufacturing.

| NO | Description | Parameter |

| 1 | Model | AKH-1500 / AKH-2000 / AKH-3000 |

| 2 | Laser Power | 1500W / 2000W / 3000W |

| 3 | Platform Size | 800×1000mm |

| 4 | Z-Axis Height | 300mm |

| 5 | Rotation Axis Diameter | 100mm |

| 6 | Cooling Method | Water Cooling |

| 7 | Collimation | CCD |

| 8 | Laser Type | Raycus / BWT / Max |

| 9 | Working Humidity | <70% No Condensation |

| 10 | Voltage | 380V |

Machine features

High Precision: The platform automatic laser welding machine ensures exceptional welding accuracy, ideal for intricate parts or detailed applications. The integration of CNC control and laser technology allows for precise control over the welding process, minimizing errors and ensuring consistent weld quality.

Increased Efficiency: With its automated functionality, the platform laser welding machine can handle repetitive welding tasks continuously and quickly. This reduces manual labor and speeds up production, making it suitable for mass production and high-volume projects.

Automated Rotation for Cylindrical Parts: When equipped with a rotary axis, the machine can easily handle metal pipes and cylindrical components, offering continuous 360-degree welding for consistent seam quality.

Real-Time Monitoring with CCD Integration: The CCD camera system enhances accuracy by allowing real-time visual monitoring of the welding process, ensuring proper alignment and enabling immediate correction of any potential issues.

Flexibility in Automation: These machines can be integrated into fully automated production lines, allowing seamless operation with minimal human intervention, which improves overall productivity and reduces labor costs.

DSW300 Double Wobble Laser Welding Head

The DSW300 double wobble laser welding head is a high-performance tool designed for precise and efficient laser welding applications.

It features a double wobble function, which allows the laser beam to oscillate in different patterns, significantly improving welding quality by reducing defects such as cracks or weak joints.

The DSW300 is also known for its high adaptability, making it suitable for various metals and alloys.

Au3tech Control System

CCD Camera

CCD camera with a blue light lamp, achieve the welding piece visible.

It allows operators to monitor the welding process live, ensuring that the weld quality is consistent and making it easier to detect and correct any issues on the fly.

Raycus Laser Generator

Raycus has an efficient and professional R&D and production team, which is the top quality in China.

The lasers have higher electro-optical conversion efficiency, higher and more stable optical quality. Low error rate, low power consumption, maintenance-free and compact.

Taiwan Delta Servo Motor

Taiwan Delta servo motors are renowned for their exceptional precision and stability. They deliver accurate positioning and smooth motion control, ensuring consistent and high-quality welds.

Delta servo motors feature rapid response times, enabling quick adjustments during welding operations. This responsiveness minimizes delays and enhances the overall efficiency of the laser welding process.

Built with robust materials and advanced engineering, Delta servo motors offer long service life and reliable performance, even in demanding industrial conditions.

Rotary Axis

The rotary axis in a platform automatic laser welding machine is a specialized device designed to hold and rotate metal pipes or cylindrical workpieces during the welding process.

The rotary axis continuously rotates the metal pipe, allowing the laser welding head to create a uniform weld seam around the entire circumference. This ensures consistent weld quality, especially for circular or complex geometric shapes.

The rotary axis firmly holds the metal pipe in place, preventing movement or misalignment during welding. This is beneficial for ensuring precision and reducing the risk of defects.

Industrial Water Chiller

Specially developed for laser equipment, excellent cooling effect.

It has safe, durable, and stable working performance with long service life.

Applications

The CNC platform automatic laser welding machine is widely applied in industries that require precise, efficient, and high-quality welding. It is commonly used in the automotive industry for welding car components, in aerospace for producing lightweight aircraft parts, and in the medical field for creating surgical instruments. Additionally, it is used in energy sectors for battery manufacturing, and metal fabrication for strong, seamless welds in mass production. Its versatility and automation make it ideal for various industrial applications.

Acctek's after-sales

Let you have no worries about our machines

-

1 to 3 years guarantee of the whole machine.

-

Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

-

Lifetime maintenance free of charge.

-

Our staff can be sent to your company to install or adjust if necessary.

-

technical support online whole life

You May Also Interested in Following Products

Related Documents

-

1

20 / Jan

Is the Laser Marking Machine Worth Buying?

This article dives deep into the factors to consider when evaluating whether a laser marking machine is the right choice for your needs, aiming to provide effective advice on choosing the right one.

-

2

13 / Jan

Does the Laser Welding Machine Require Shielding Gas?

In this article, we’ll explore the role of shielding gas in laser welding, its types, and useful tips for your welding operation to help you make an informed decision based on your welding needs.

-

3

06 / Jan

Ideal Way to Remove Rust from Metal: Laser Cleaning System

People often ask, "Is laser rust removal effective?" The answer is: Yes, laser rust removal is very effective. This is reflected in various aspects such as speed, effect and safety.

-

4

30 / Dec

What is the Lifespan of a CNC Router?

In this article, we will explore the factors that influence the lifespan of your CNC router and provide insights into extending its lifespan, aiming to allow you to get the most out of your investment.

-

5

23 / Dec

Can a CNC Router Cut Aluminum Effectively?

"Can CNC routers cut aluminum?" The answer is yes. In this article, we will dive into the factors that influence the effectiveness of cutting aluminum with a CNC router, aiming to give you the confidence to tackle your aluminum cutting projects.

-

6

16 / Dec

How Thick Can a Fiber Laser Cutting Machine Cut?

In this article, we will explore the maximum thickness that 1KW-40KW fiber laser cutting machines can cut various materials such as carbon steel, stainless steel, aluminum and copper.