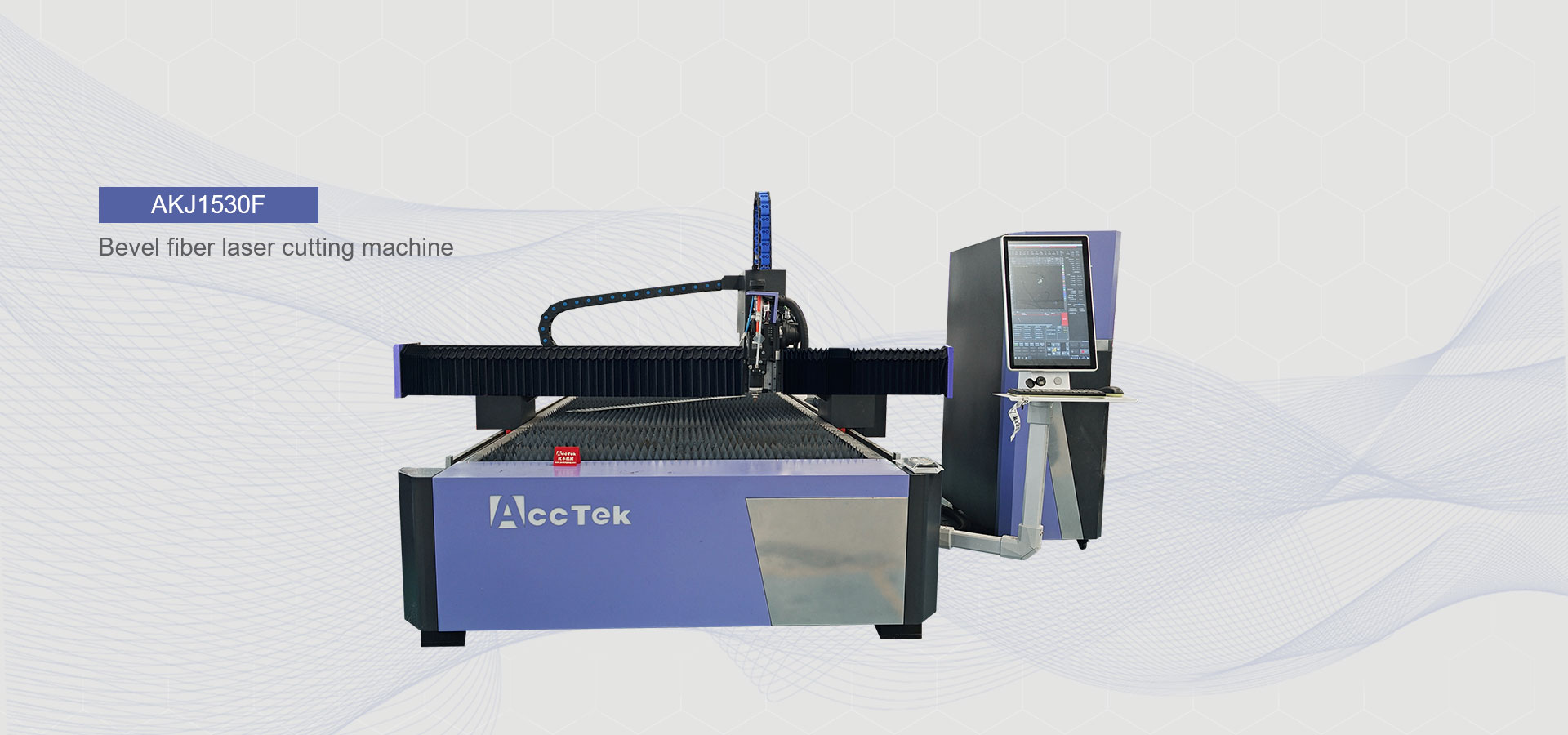

Bevel Fiber Laser Cutting Machine for Sheet Metal

Model:

AKJ1530F/

Category:

Fiber Laser Cutting Machine

Brand:

ACCTEK

price:

$46300-$182000

Description:

AccTek bevel fiber laser cutting machine can realize the maximum 45°bevel cutting on the plane, which streamlines the metal bevel cutting process and makes perfect bevels in one single shot. The cutting parts have high dimensional accuracy and high surface quality, which greatly improves efficiency, guarantees quality, and saves resources.

| 1 | Model | AKJ1530F2 / AKJ1530F3 |

| 2 | Laser power | 1500W/2000W/3000W/4000W/6000W/8000W/12000W/20000W(Optional) |

| 3 | Machinable Bevel | Yes |

| 4 | Working Area | 1500 x 3000mm |

| 5 | Repeat Positioning Accuracy | ±0.02mm |

| 6 | Maximum Speed | 120m/min |

| 7 | Max Acceleration | 1.0G |

| 8 | Max Cutting Speed | 80m/min |

| 9 | Motor & Driver | Japanese YASKAWA |

| 10 | Laser Head | Boci |

| 11 | Laser Type | Raycus / IPG / Max |

| 12 | Voltage | 380V 50Hz/60Hz/60A |

| 13 | Body Weight | 3500Kg / 4000Kg |

Machine features

Streamlined process, ultra-high processing efficiency, and superior bevel accuracy.

The produced cut-offs are ideal for zero gap welding. No extra cutting and subsequent grinding will be needed, so that you benefit from a 75% efficiency boost than traditional metal cutters.

The bevel cutting solution combines CNC controller, rotary axis, nesting software and laser cutting head. It provides extensive support for industries such as steel structures, shipyards, subcontracting, engineering machinery and so forth.

Boci BLT441 Plane Bevel Cutting Head

BLT441 intelligent plane bevel cutting head can achieve 45° bevel and plane cutting.

It has intelligent technologies such as air pressure monitoring, lens temperature monitoring, anti-collision, and anti-explosion.

It is easy to debug, stable cutting, and excellent performance.

BOCHU FSCUT9000A Controller System

FSCUT9000A cutting controller applies to mid/high power 2D bevel cutting, maximizing material savings.

Featuring efficient and user-friendly mechanical calibration, precision compensation, and bevel nesting, it is widely used in sheet metal processing.

Raycus Laser Generator

Raycus has an efficient and professional R&D and production team, which is the top quality in China.

The lasers have higher electro-optical conversion efficiency, higher and more stable optical quality, ensuring a more stable and more sophisticated cutting effect in thick sheet cutting.

This series of lasers apply to many application scenarios, with a narrow seam of the cut sheet and a bright section.

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries.

Light weight, high strength, no deformation. Molded and framed by integral steel mold and die-casting technology, light crossbeam enables equipment a high operation speed, improving processing efficiency and processing quality.

Heavy Duty Frame

The strongest frame in China CNC machine industry. Thickness of the rectangular pipe wall is 10mm, super stable even at high power cutting.

Increases the stability of the guide rail so as to effectively avoid the deformation of the bed. Lifetime is up to 25 years.

Japanese Yaskawa Servo Motor

Faster speed with signal feedback, realizes acceleration and deceleration at high speed, and has fast response.

Low heat, low noise, high speed and high precision.

Strong anti-interference ability and strong anti-overload capability.

HIWIN Guide Rails

Rail works with slider, drive the machine move.

Smooth running, high-speed silent, high abrasion resistance, and good load-carrying capacity.

Applications

Applied Materials: carbon steel, stainless steel, copper, brass, aluminum alloy, galvanized sheet, etc.

Application Industries: It is suitable for a variety of metal processing scenarios, such as automotive, aerospace, mechanical manufacturing, hardware manufacturing, etc.

The bevel laser cutting machine can realize the efficient processing of various metal materials, greatly improve production efficiency, and also ensure processing quality. In addition, it can also realize the processing of various complex shapes, bringing higher processing accuracy and better processing results for enterprises.

Acctek's after-sales

Let you have no worries about our machines

-

1 to 3 years guarantee of the whole machine.

-

Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

-

Lifetime maintenance free of charge.

-

Our staff can be sent to your company to install or adjust if necessary.

-

technical support online whole life

You May Also Interested in Following Products

Related Documents

-

1

20 / Jan

Is the Laser Marking Machine Worth Buying?

This article dives deep into the factors to consider when evaluating whether a laser marking machine is the right choice for your needs, aiming to provide effective advice on choosing the right one.

-

2

13 / Jan

Does the Laser Welding Machine Require Shielding Gas?

In this article, we’ll explore the role of shielding gas in laser welding, its types, and useful tips for your welding operation to help you make an informed decision based on your welding needs.

-

3

06 / Jan

Ideal Way to Remove Rust from Metal: Laser Cleaning System

People often ask, "Is laser rust removal effective?" The answer is: Yes, laser rust removal is very effective. This is reflected in various aspects such as speed, effect and safety.

-

4

30 / Dec

What is the Lifespan of a CNC Router?

In this article, we will explore the factors that influence the lifespan of your CNC router and provide insights into extending its lifespan, aiming to allow you to get the most out of your investment.

-

5

23 / Dec

Can a CNC Router Cut Aluminum Effectively?

"Can CNC routers cut aluminum?" The answer is yes. In this article, we will dive into the factors that influence the effectiveness of cutting aluminum with a CNC router, aiming to give you the confidence to tackle your aluminum cutting projects.

-

6

16 / Dec

How Thick Can a Fiber Laser Cutting Machine Cut?

In this article, we will explore the maximum thickness that 1KW-40KW fiber laser cutting machines can cut various materials such as carbon steel, stainless steel, aluminum and copper.