The 4 most common types of laser marking machine

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

This article introduces four common laser marking machines for you. Learn about their features and advantages to make the right choice for your marking project.

Laser marking machine is a long-term marker with a laser beam on the surface of various materials. The effect of the mark is to reveal deep substances through the evaporation of the surface material or the chemical and physical changes of the surface material or blew some substances by bleaching. Patters, text. At present, there are two recognized principles:

The "heat processing" with a high-energy density laser beam (this is a concentrated energy flow), is illuminated on the surface of the processing material. Coating) The phenomenon of temperature rises, abnormal, metamorphosis, melting, deformation, evaporation, and other phenomena.

"Cold treatment" has high negative load (ultraviolet) photons, which can interrupt the material (especially organic materials) or chemical bonds in the surrounding medium to damage the non-heat process of the material. This cold treatment has a special significance in laser markers, because it is not hot melting, but the side effects of cold peeling of "heat damage" and chemical keys. It produces heating or heat deformation. For example, in the electronics industry, chemical membranes are deposited on basic materials to deposit chemical membranes on basic materials and open a narrow slot on the semiconductor substrate.

With the continuous progress of technology, it can be said that the laser marker machine has been applied to multiple fields, trademark printing of metal and glass products, personalized DIY pattern printing, barcode printing, etc. Due to the widespread application of powerful laser coding technology and the identity recognition industry, laser markers derive various types of models. Each model will have certain differences in itself, including different laser wavelets, different laser principles, visibility of laser, and different frequencies. To allow everyone to understand the laser marker products suitable for their production line, here briefly introduce several common laser marker types.

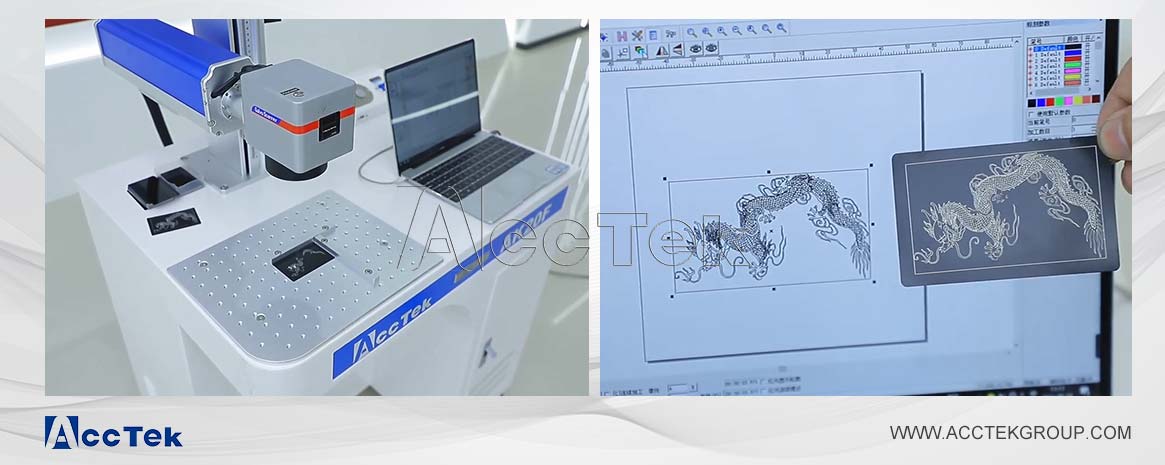

Fiber laser marker machine

Fiber laser marking machine is a relatively mature laser marker equipment. It is mainly used to make marks with metal materials, or it can also be used for certain non-metallic materials. Fiber laser marking machines use a fiber laser source, which employs optical fibers doped with rare-earth elements like ytterbium to generate the laser beam. These machines are known for their high efficiency, excellent beam quality, and long service life. Fiber laser marking machines offer precise and fast marking capabilities, making them popular in industries like automotive, aerospace, and electronics. Common applications include marking serial numbers, barcodes, logos, and other identifiers on metal parts, tools, electronic components, and jewelry.

UV Laser Marking Machine

UV laser marking machines utilize ultraviolet (UV) lasers to mark or engrave materials, typically at a wavelength of 355 nm. These lasers operate at shorter wavelengths compared to traditional fiber or CO2 lasers. The UV laser creates high-energy photons that break the chemical bonds on the surface of the material, resulting in a "cold" marking process. So UV laser marking machines are well-suited for marking materials that are highly sensitive to heat, such as certain plastics, glass, and ceramics. They produce very fine and precise marks, making them suitable for intricate designs and small-sized markings. UV laser marking machines are commonly used in industries like semiconductors, electronics, medical devices, and packaging for marking electronic components, PCBs (printed circuit boards), glass, and plastics.

CO2 Laser Marking Machine

CO2 laser marking machines use carbon dioxide (CO2) gas as the laser medium to generate the laser beam, which produces a laser beam at a wavelength of 10.6 micrometers. These machines operate at longer wavelengths compared to fiber or UV lasers. These lasers are especially effective for non-metal materials and can mark a wide range of materials including plastics, wood, paper, glass, and ceramics. They are especially well-suited for organic materials and are often used in applications where deep engraving or cutting is required. Common applications include marking packaging materials, wood products, rubber, textiles, and acrylics. They are also used in industries like signage, advertising, and arts and crafts.

MOPA Laser Marking Machine

MOPA laser marking machines are a type of fiber laser marking system that utilizes a MOPA laser source. MOPA lasers offer additional flexibility in pulse duration and frequency compared to traditional fiber lasers. This allows for more control over the laser's parameters, which can be advantageous for applications requiring precise control over the marking process. MOPA laser marking machines are often used in applications where control over pulse duration and frequency is important, particularly effective for creating high-contrast marks on materials that are typically challenging, such as anodized aluminum. They find applications in color marks on metals, fine engraving on electronics, and marking on delicate plastic surfaces.

Each type of laser marking machine has its specific strengths and is suited for different applications based on the material to be marked and the desired marking outcome. Fiber lasers are great for metals, UV lasers for sensitive materials, CO2 lasers for organic materials, and MOPA lasers for high-precision and color-marking applications.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd