How many watts do I need for fiber laser cutting?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

This article introduces you from many aspects how to choose the correct power for a fiber laser cutting machine. By understanding them, you can achieve higher cutting quality and efficiency.

Fiber laser cutting machine has outstanding advantages in sheet metal cutting. It relies on the high-temperature melting generated by the laser to irradiate the surface of the sheet metal and controls the displacement through numerical control to achieve the purpose of cutting. The advantages of laser cutting are no deformation, high flexibility, small kerf, smooth cross-section, and no burrs. It can cut arbitrary complex graphic workpieces. For different plate thicknesses, power plays a vital role in cutting quality and speed.

Fiber laser cutting machines with different powers have different cutting capabilities and thickness ranges. Therefore, when choosing a suitable fiber laser cutting machine, the configuration of the corresponding fiber laser cutting machine is usually selected according to the material to be processed and cut. So, how to choose the power of low, medium, and high-power fiber laser cutting machines? Let's take a look at how to choose the power of the laser cutting machine and the requirements for laser cutting power.

How to choose laser power?

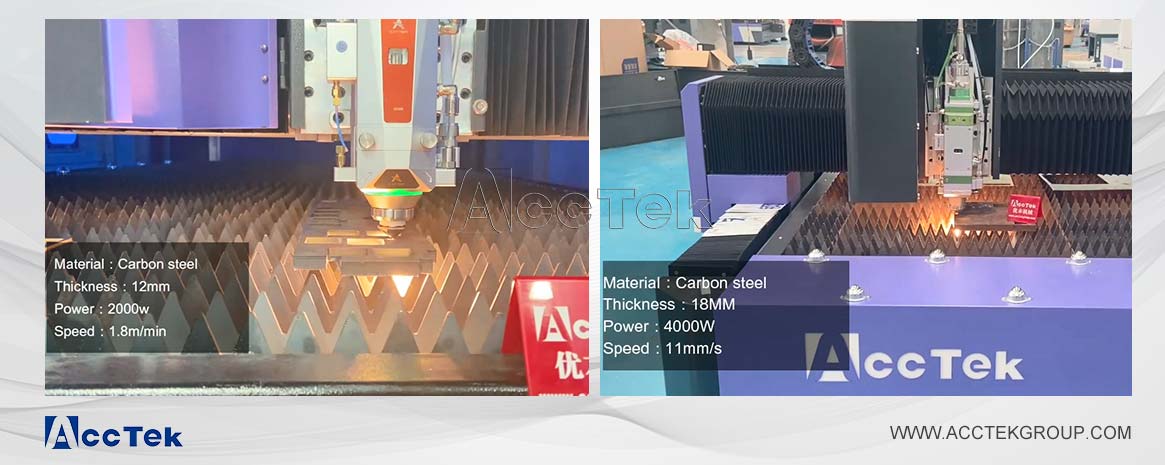

The material cut by fiber laser cutting machine is metal, mainly stainless steel, carbon steel, aluminum, brass, and so on. The achievable cut thickness increases with increasing laser power.

The power of fiber laser cutting machines mainly depends on the laser source. In the market, 4000W and above are generally called high power, power between 2000w-4000w is called medium power, and power below 2000W is called low power. Judging from the current demand, the market has a large demand for 2000W fiber laser cutting machines, which can meet most of the cutting needs. Cutting speeds above 2000W may be faster, but also more expensive. Laser power is one of the main factors that directly affect the price of laser cutting machines.

For thinner stainless steel and carbon steel plates, a low-power fiber laser cutting machine can be used, which has a good cutting effect and ensures fast cutting speed, which not only ensures work efficiency but also saves costs. Therefore, when we choose a laser cutting machine, we must make a reasonable choice according to our own metal material and material thickness, and we cannot blindly pursue high power. Of course, if you want to cut both thick plates and thin plates and have high requirements for production capacity, then a moderately priced high-power laser cutting machine is also a better choice. By properly adjusting the cutting speed and changing the auxiliary gas, the high-power laser cutting machine can control the cutting quality well.

First, let's take carbon steel as an example. A 1000W machine can cut carbon steel below 8mm, and a 1500W machine can cut carbon steel below 12mm. Next, we take stainless steel as an example. The 1000W machine cuts stainless steel below 4mm, and a 1500W machine can reach about 6mm. It can be seen that when facing 1000W and 1500W fiber laser cutting machines, 1500W fiber laser cutting machines are a more sensible choice.

Precautions for choosing the right laser cutting machine power

Material Type and Thickness: A fiber laser with a power of 100W to 2000W is typically sufficient for cutting thin metals like stainless steel, carbon steel, aluminum, and brass. For medium thicknesses materials, a power range of 2000W to 4000W is recommended. This range balances speed and quality for metals like stainless steel, carbon steel, and aluminum. Cutting thicker materials effectively requires higher power, usually in the range of 6000W or more. This ensures clean cuts and efficient processing for thicker sections of metals.

Cutting Speed: Higher power lasers can cut materials faster. If high productivity is crucial for your operation, opting for a higher wattage laser will allow you to cut through materials more quickly.

Types of Cuts: Simple, straight cuts can often be achieved with lower power lasers. Complex, intricate cuts may necessitate higher power to maintain accuracy and speed, especially in thicker materials.

Cost Considerations: Higher power lasers are generally more expensive not only to purchase but also to operate and maintain due to higher energy consumption and more complex cooling systems. Assess your budget and determine the balance between upfront investment and long-term operational costs.

Future Needs: Consider future scalability and potential increases in cutting requirements. It might be prudent to invest in a slightly higher power laser than is currently needed to accommodate future growth.

Manufacturer Recommendations: Consult with the laser cutting machine manufacturers. They often provide detailed guidelines and support to help you choose the right power based on your specific applications and materials.

Trial and Testing: If possible, conduct trials with different power levels to see the real-world impact on your specific materials and cutting requirements. This practical approach can provide valuable insights into the best power level for your needs.

Choosing the right power for your laser cutting machine is a balance between the type and thickness of materials, cutting speed, precision, cost, and future needs. Carefully evaluate these factors and consult with manufacturers or industry experts to make an informed decision that suits your operational requirements and goals.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd