High performance CNC router for sale

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

In this article, we'll explore some of the most important things to keep in mind when shopping for a CNC router, and we'll some of the models available on the market.

CNC routers are essential machines for modern woodworking, metalworking, and many other industries. They are computer-controlled tools that can precisely carve, mill, drill, and engrave a wide range of materials to produce complex and intricate parts, products, and designs. With the increasing demand for high-precision, versatile, and efficient machines, CNC routers are becoming increasingly popular in many different applications, such as sign-making, cabinetry, prototyping, model-making, and more.

If you're looking for a high-performance CNC router machine for sale, there are many different factors you need to consider, including the size and type of the machine, the type of materials you'll be working with, the features you need, and your budget. In this article, we'll explore some of the most important things to keep in mind when shopping for a CNC router, and we'll highlight some of the top models available on the market today.

Some of the most important include the type of controller used, the size and rigidity of the machine frame, the quality of the motors and drives, and the accuracy of the cutting and positioning systems.

One of the most important components of any CNC router is the controller. The controller is responsible for interpreting the design file and executing the cutting or engraving operations. High-performance controllers are typically faster, more reliable, and more capable than those used in lower-end machines. They may also feature more advanced software, which allows for more precise control over the cutting process and more sophisticated operations, such as multi-axis machining.

The size and rigidity of the machine frame is also a critical factor in determining performance. A larger, more rigid machine will be more stable and accurate than a smaller, less rigid one. This is particularly important for larger or more complex projects, where precise cuts and accurate engravings are essential.

Another important aspect of high-performance CNC routers is the quality of the motors and drives. Motors and drives play a critical role in determining the speed and accuracy of the machine. High-performance machines typically feature more powerful and precise motors and drives, which allow them to perform faster and more accurately than lower-end machines.

Finally, the accuracy of the cutting and positioning systems is also a critical factor in determining performance. High-performance CNC routers typically feature more precise and accurate cutting systems, which allow them to produce more consistent and accurate cuts and engravings.

There are many different models of high-performance CNC routers available on the market today, each with its own set of capabilities and features. Here are some of the top high-performance CNC router machines for sale:

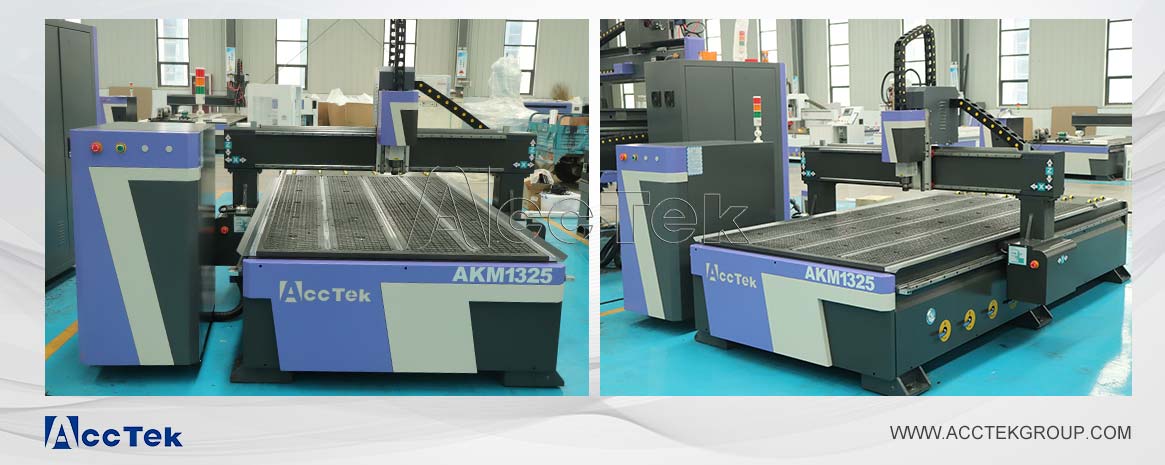

3 Axis CNC 1325

it has 3 axes of motion (X, Y, and Z) and a working area of 1300*2500mm in size. 3 axis cnc router is commonly used in woodworking, metalworking, and plastic processing for tasks such as cutting, engraving, and milling.

The 3 axes of motion allow the machine to move in different directions and create more complex shapes and designs. The working area of 1325mm indicates the maximum size of the material that can be processed by the machine.it is a compact and affordable standard model that is perfect for hobbyists, makers, and small workshops.

ATC CNC Router 1530

ATC CNC router 1530 refers to an automatic tool changer (ATC) computer numerical control (CNC) router with a working area of 1500mm x 3000mm.The automatic tool changer feature of the ATC CNC Router 1530 allows for multiple cutting tools to be stored and quickly changed during the machining process, reducing the downtime required for manual tool changes and increasing the overall efficiency of the machine .it is a versatile and efficient model that is ideal for small to medium-sized businesses.

4 Aixs CNC Router

The four axes in a 4-axis CNC router are typically the X, Y, Z, and A (rotary) axes. The X and Y axes control the movement of the cutting tool across the X-Y plane, while the Z axis controls the depth of the cut. The A axis allows for rotary cutting, which is useful for cutting cylindrical shapes and creating decorative elements such as flutes and spirals.

4-axis CNC routers are commonly used in a variety of industries, including woodworking, plastic fabrication, and sign making. They are also used for creating molds and prototypes, as well as for producing small to medium-sized production runs of parts. The additional axis of motion in a 4-axis CNC router provides greater flexibility and versatility in terms of the types of shapes and designs that can be created.

In conclusion, a high-performance CNC router can be an excellent investment for a range of industries, including woodworking, metalworking, plastics processing, and more. With careful research and consideration of your needs and budget, you can find the right machine to help you achieve your goals and grow your business.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd