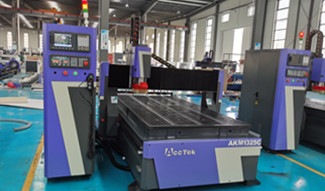

Industrial ATC CNC router with automatic tool changer for sale

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

ATC CNC router is a typical product of high-end CNC machine. Its high-performance configuration greatly improves the cutting efficiency and engraving accuracy of the machine.

CNC router is the main equipment of industrial processing now. When your workshop has the need of mass production, it will waste your time and labor cost when the machine stops to change the tool. At this time, purchasing a fully automatic tool changer CNC router can help you better improve production and profits, because it can complete the automatic tool change in only a few seconds without downtime. This is very advantageous for mass production companies and users who process complex design projects.

ATC CNC router is typical products of high-end machine tools. The development and application of its high-performance configuration such as ATC spindle, servo motor, and professional CNC system greatly improves the cutting efficiency and engraving accuracy of the machine. In order to meet the requirements of high efficiency and high precision of CNC machine tools, the high speed of automatic tool changer, which is one of the important components of ATC CNC router, has also become an important technical content of high-end CNC machining centers. With the increase of cutting speed and the continuous shortening of cutting time, the requirement of industrial ATC CNC router for tool change time is gradually increasing, and the speed of machine tool change has become an important indicator of high-level machining centers.

Why choose ATC CNC Router?

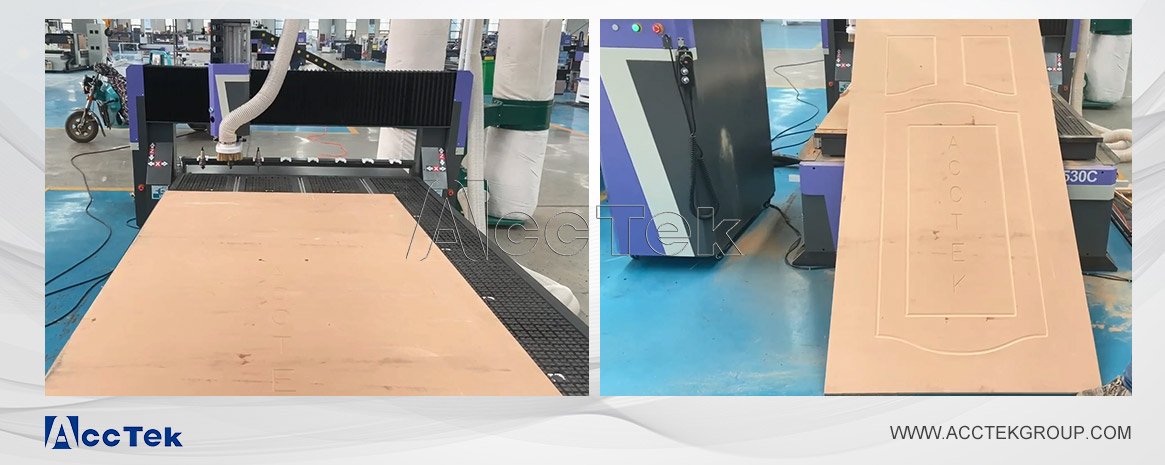

CNC routers are most widely used in the manufacture of furniture industry and woodworking projects. For these woodworking products, multiple processes are often required to complete the production of a workpiece. Especially custom furniture or art installations, these products often require multiple processes on a single sheet. In this case, when machining with a CNC router, it is necessary to replace multiple tools to complete. For CNC machines with only one tool, manually changing tools can cost valuable production time and can introduce human error.

The ACCTEK industrial ATC CNC router can load 4-12 different tools according to the user's needs. The professional CNC system directs the tools to complete the automatic tool change to shorten the production time, and eliminates the need for the CNC machine operator to change and reset the tool individually. When it is necessary to use different tools on the same sheet for different types of machining, the automatic tool change system allows us to complete the entire job quickly and easily. ATC cnc router machines can often perform operations that are done on other engraving equipment, eliminating the need to add additional machines to the shop.

For the ATC CNC router, not only does the automatic tool change system save you more time, the configuration of the vacuum table also makes your production easier and more efficient. Vacuum worktable is very common in CNC router machines, especially for the processing of large-sized materials such as wooden doors and cabinet boards, the vacuum adsorption method can fix the board on the worktable faster. You only need to put the wood to be processed on the table, then turn on the vacuum suction switch, and the wood can be firmly fixed on the machine table. It saves you valuable time by not requiring the machine operator to spend as much time manually clamping the boards in multiple places.

The vacuum table can be divided into multiple areas according to the user's needs, and each area is controlled by an independent gate valve, so even when processing small-sized sheets, you can use a single vacuum area, thereby reducing the waste of electricity. The advantage of the vacuum table is also reflected in its strong fixation to the plate, even the thin plate can be firmly fixed, avoiding the problem of poor machining accuracy caused by the vibration of the plate during the processing.

ACCTEK industrial ATC CNC routers are all equipped with 3.0KW double-bag dust collectors, which provide greater convenience for the production of woodworking projects. During the process of engraving and cutting wood, the dust removal brush installed on the main shaft collects most of the wood chips into the dust bag, which can create a clean workshop environment for users. You don't have to waste more time cleaning the machine or work area, it's easier.

The price of CNC router with automatic tool changer is often more than 10,000 US dollars. Although it is more expensive than ordinary 3 axis CNC router, compared with its advantages, these costs can be recovered in a short time. The efficiency of the ATC CNC router means that you can produce more workpieces and thus get more customers; the high precision of the ATC CNC router means that you can improve the quality of the workpiece and thus increase the price of the product. These advantages can help you gain a larger market and gain the trust of customers, high quality means high returns. Of course, the choice of CNC machine tools should be purchased according to their own needs. If your workshop does not have too many requirements for the speed and accuracy of the machine, the ordinary 3 axis CNC engraving machine will save you more costs while meeting the processing needs.

ACCTEK CNC provides you with more customized services for CNC machine, all based on your needs. Contact online for professional CNC router buying advice.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd