Which laser marking machine is used for plastic materials?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

Nowadays, plastic has become the most commonly used packaging material, so which laser marking machine is more suitable for marking the surface of plastic products?

Nowadays, plastics have become the most commonly used packaging materials, and we can often see identification marks such as corporate trademarks, barcodes and numbers on plastic products. These marks are usually made by printing, embossing, punching, engraving, etc. The use of laser marking machine to mark the surface of plastic products is an advanced marking technology that has fast processing speed, can maintain the inherent surface characteristics of plastic products, and make text or pattern and plastic a unified whole. So which laser marking machine is more suitable for marking the surface of plastic products?

Different types of lasers emit light of different wavelengths and have different penetration capabilities. Therefore, marking machines equipped with different lasers differ in marking quality and marking speed. Fiber laser marking machine, UV laser marking machine, CO2 laser marking machine can all mark on plastic. However, their application scope and effects are different. Here are their specific application scenarios:

Fiber Laser Marking Machine

It is suitable for marking plastic materials with high ignition point (such as PC, ABS). As we all know, the fiber laser marking machine mainly engraves and marks metal products. In fact, as long as the parameters are adjusted properly, the fiber laser marking machine can also mark some plastic products. By choosing the right parameters, the laser will only vaporize a thin layer of the surface of the plastic without burning the plastic itself. But even so, the fiber laser marking machine is only suitable for marking some plastic products. If your workshop only marks non-metallic materials, it is recommended to choose the CO2 laser marking machine.

CO2 Laser Marking Machine

Mainly used for acrylic and rubber. The CO2 laser marking machine has the same good focusing ability as the metal laser marking machine, so it is very suitable for fine marking of plastic products. The diode-pumped solid-state laser has a high beam quality, which enables the laser beam to obtain a small focusing diameter during the marking process. At present, CO2 laser marking machine also has an irreplaceable role in plastics.

UV laser marking machine

Applicable to all plastic materials, mainly used in the high-end market of ultra-fine processing. Because the smaller line width of UV is 0.01mm, the marking accuracy of UV laser marking machine is better than other marking methods.

Advantages of Laser Marking Plastics

When marking the surface of plastic products, laser marking machine has the advantages of low cost and high flexibility compared with traditional mechanical engraving, chemical etching, screen printing, ink printing and other methods. The laser marking machine can be controlled by a computer system, which is very simple and convenient to complete the permanent engraving of the pattern to be marked on the surface of the material. The laser marking process does not require consumables, does not produce chemical pollution, and because it is non-contact marking, it will not cause damage to the surface of the material, which is very safe and environmentally friendly.

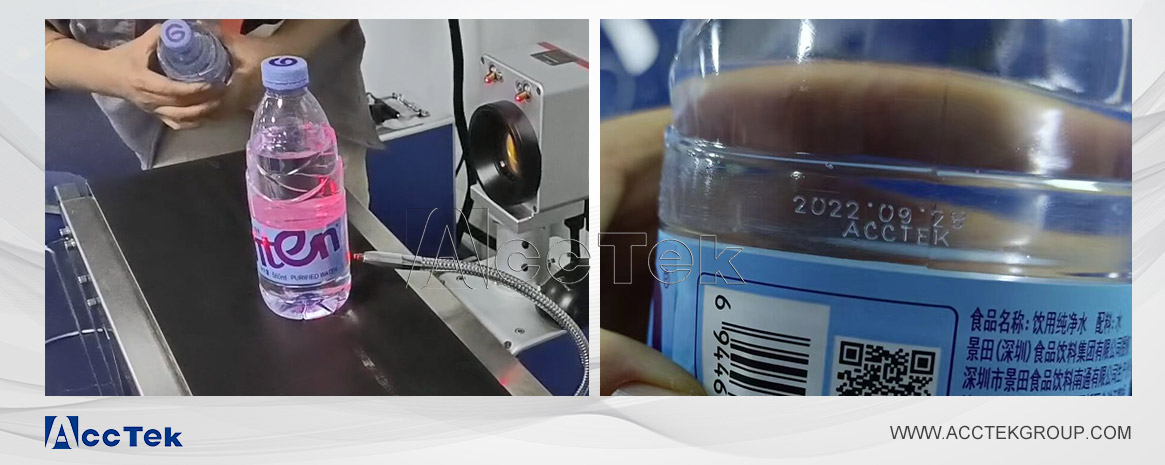

The laser marking machine uses a laser beam to directly generate marks on the plastic surface, including marks, codes, characters, numbers, patterns, lines, two-dimensional codes, etc. ACCTEK laser marking machines can be used to permanently, quickly and efficiently mark many different types of commercial plastics such as polycarbonate, ABS, polyamide and more. Due to the short installation time, flexibility and ease of use of the laser marking machine, small batch laser marking can be carried out in the most economical way.

Laser marking machine marks plastic, can the logo be wiped off?

The patterns and numbers after laser marking are permanent and cannot be wiped off unless the surface is scraped off. Therefore, using laser marking machine to mark product tracking code, QR code, brand logo and other information can play a good anti-counterfeiting role.

The types of laser marking machines used for plastics of different materials and plastics of different purity of the same material will be different. In addition, each customer has different requirements for the marking effect. Therefore, before you buy a laser marking machine, you can contact the laser marking machine manufacturer and send your samples to them to photograph the marking process and marking effect. In this way, you can more accurately determine which laser marking machine is more suitable for the marking needs of your product.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd