Correct use of auxiliary gas for laser welding machine

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

What is the effect of auxiliary gas on laser welding machine? How should I use auxiliary gas correctly to help achieve the best welding effect?

Laser welding machine is a very popular welding equipment in recent years, it has been maturely used in many fields, such as automobile manufacturing, stainless steel kitchen utensils, household appliances, bathroom products and other fields. As a direction of laser application, laser welding machine has greater advantages compared with traditional welding equipment. In order to ensure the good welding effect of the handheld laser welding machine at work, it is very important to use the auxiliary gas correctly. So what does the auxiliary gas do for laser welding? How should I use the assist gas correctly?

The role of auxiliary gas in laser welding

1. The auxiliary gas can effectively protect the weld pool to reduce or even avoid oxidation.

2. Correctly blowing in the auxiliary gas can effectively reduce the spatter generated in the process of welding metal, thereby protecting the focusing lens of the laser welder from the sputtering of liquid droplets. Especially in the case of high-power laser welding, since its ejection becomes very powerful, it is more necessary to protect the lens at this time.

3. The auxiliary gas can promote the uniform spreading of the weld pool when it solidifies, so that the weld is formed uniformly and beautifully.

4. The auxiliary gas is very effective for dissipating the plasma shielding generated by high-power laser welding, thereby improving the effective utilization of the laser.

5. Using nitrogen and argon as protective gas, it can isolate oxygen, nitrogen and hydrogen in the air to prevent the weld from oxidizing and generating pores.

Auxiliary gases provide several positive benefits for handheld laser welding machine, but choosing the wrong gas can cause cracks in the weld, reducing the firmness of the weld location. In addition to the wrong gas type adversely affecting welding, wrong gas flow can also adversely affect laser welding. Regardless of whether the gas flow is too large or too small, the wrong gas injection flow rate may cause more serious oxidation of the weld, and may also cause the weld pool metal to be seriously disturbed by external forces, causing the weld to collapse or form unevenly.

The wrong way of blowing the auxiliary gas will not only not protect and promote the laser welding, but will even have a negative impact on the weld formation. Therefore, it is very important to choose the correct auxiliary gas and the correct blowing method for different metal welding processes.

Correct use of auxiliary gas

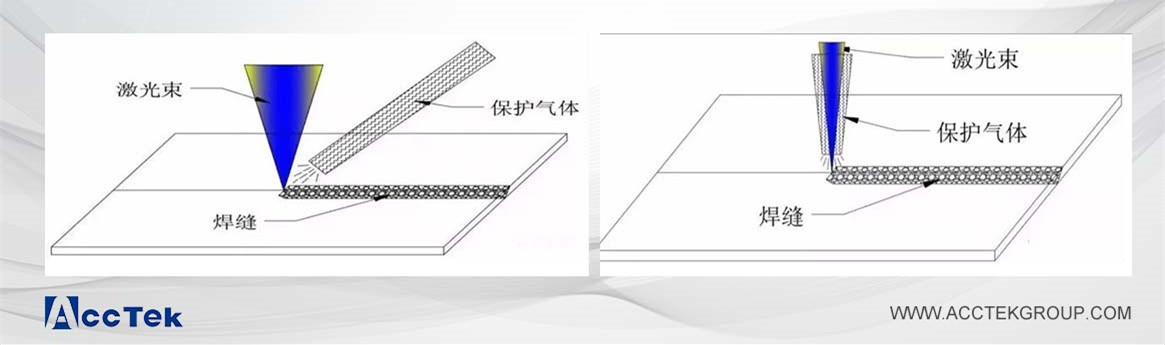

At present, there are two main ways of blowing auxiliary gas, one is side-shaft side blowing protective gas; the other is coaxial protective gas. The specific selection of the two blowing methods is determined by comprehensive consideration of various aspects. Generally, the method of side blowing protective gas is recommended.

Type of auxiliary gas

Nitrogen

Nitrogen is the cheapest auxiliary gas, but it has limitations in its use and is not suitable for all laser welding processes. For example, some stainless steel welding types are not used, mainly due to metallurgical concerns. Such as absorption, sometimes air holes are created in the overlapping area.

Argon

The density of argon gas is higher, the protection effect is better, and the metal surface is smoother after welding. However, it is easy to be ionized by high temperature metal plasma, which will shield part of the beam from the workpiece, reduce the effective power of laser welding, and hinder the welding speed and penetration.

Helium

Helium works well and doesn't ionize easily, so it doesn't affect the laser transmission and allows the laser to pass through. Helium allows the beam energy to reach the workpiece surface directly without hindrance, and has strong oxidation resistance. It is a more effective shielding gas for laser welding machines, but helium is generally more expensive than other auxiliary gases.

I hope you can use the auxiliary gas correctly in the process of operating the handheld laser welding machine. As long as the gas type, gas flow and blowing method are selected correctly, the ideal welding effect can be obtained, and the service life of the laser welder will be prolonged.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd