Handheld laser cleaning machine for industrial use

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

Handheld laser cleaning machine is a cleaning work equipment used in various industries in industrial production.

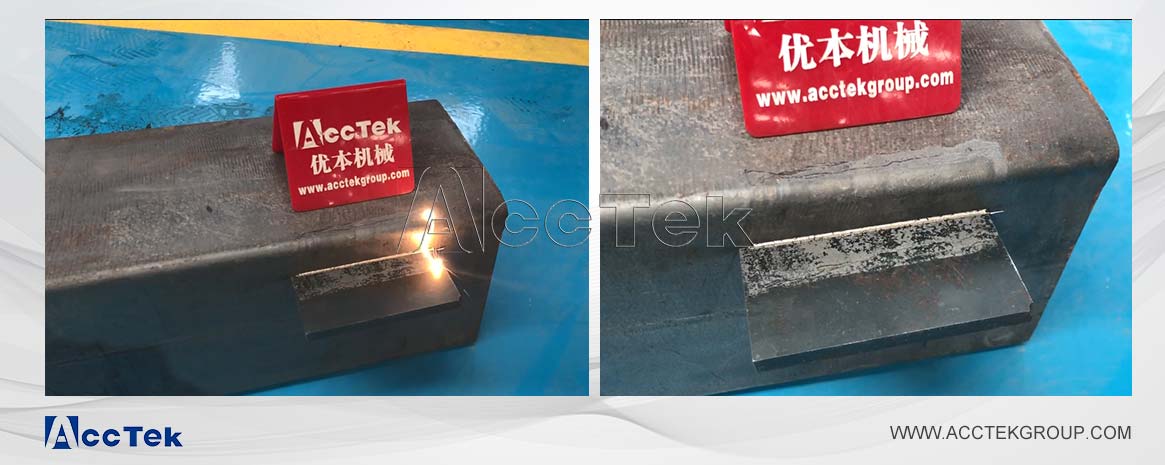

Today, with the rapid development of globalization, the efficiency of industrial production has been greatly improved, and the quality of products has been continuously improved while realizing the mass production of industrial raw materials.Now, the application of the new handheld laser cleaning machine makes cleaning in industrial manufacturing simple, and it can clean the stains, oil stains, rust and other pollutants on the surface of the product with maximum efficiency to ensure the quality of the product.

laser rust removal gun is the best way to remove rust. Laser rust removal can perfectly replace manual rust removal and chemical cleaner rust removal. Laser rust removal has higher precision and lower repeat costs. cleaning method. The laser rust removal machine only generates a small amount of dust during laser cleaning, which makes the cleaning process safer and more convenient for workers.

The handheld laser cleaning machine meets the equipment cleaning requirements in the shipbuilding industry, auto parts, rubber molds, machine tools, environmental protection industries and other fields.

The traditional cleaning methods of mold cleaning include sandblasting, ultrasonic or carbon dioxide cleaning, etc. The traditional cleaning is to use chemical solvents, high heat, and then cooling to clean, which takes a long time and damages the accuracy of the original mold. The laser rust removal gun is used to clean the mold, which is easy to use, does not produce toxic gases, and does not affect the safety of the working environment; it saves time, avoids mold damage, and saves raw materials.

Laser welding preparation is one of the many applications of laser cleaning, the handheld laser rust removal machine is beneficial for cleaning the metal and aluminum surface layers of ferrous and non-ferrous metals, lubricants and other contaminants in preparation for high quality welding. It also ensures smooth and non-porous brazing seams.

The electronics industry needs high-precision decontamination. Laser cleaning can remove oxides. Laser rust removal by laser rust removal gun is non-contact and will not damage pins. oxide to ensure optimal electrical contact.

Traditional cleaning technology requires a lot of labor to clean each part, which is not only expensive but also easy to damage the parts. Cleaning by laser machine can reduce labor costs and realize automatic or semi-automatic cleaning. The hand-held laser cleaning machine can restore the surface of the material to its original state without manual grinding or the use of chemical cleaners to avoid secondary damage during the cleaning process. The use of laser cleaning and rust removal is convenient, fast and efficient, and can be applied to different industrial productions, greatly reducing production costs and improving work efficiency and product quality.

laser rust removal gun is the best way to remove rust. Laser rust removal can perfectly replace manual rust removal and chemical cleaner rust removal. Laser rust removal has higher precision and lower repeat costs. cleaning method. The laser rust removal machine only generates a small amount of dust during laser cleaning, which makes the cleaning process safer and more convenient for workers.

The handheld laser cleaning machine meets the equipment cleaning requirements in the shipbuilding industry, auto parts, rubber molds, machine tools, environmental protection industries and other fields.

The traditional cleaning methods of mold cleaning include sandblasting, ultrasonic or carbon dioxide cleaning, etc. The traditional cleaning is to use chemical solvents, high heat, and then cooling to clean, which takes a long time and damages the accuracy of the original mold. The laser rust removal gun is used to clean the mold, which is easy to use, does not produce toxic gases, and does not affect the safety of the working environment; it saves time, avoids mold damage, and saves raw materials.

Laser welding preparation is one of the many applications of laser cleaning, the handheld laser rust removal machine is beneficial for cleaning the metal and aluminum surface layers of ferrous and non-ferrous metals, lubricants and other contaminants in preparation for high quality welding. It also ensures smooth and non-porous brazing seams.

The electronics industry needs high-precision decontamination. Laser cleaning can remove oxides. Laser rust removal by laser rust removal gun is non-contact and will not damage pins. oxide to ensure optimal electrical contact.

Traditional cleaning technology requires a lot of labor to clean each part, which is not only expensive but also easy to damage the parts. Cleaning by laser machine can reduce labor costs and realize automatic or semi-automatic cleaning. The hand-held laser cleaning machine can restore the surface of the material to its original state without manual grinding or the use of chemical cleaners to avoid secondary damage during the cleaning process. The use of laser cleaning and rust removal is convenient, fast and efficient, and can be applied to different industrial productions, greatly reducing production costs and improving work efficiency and product quality.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd