How well do you know about CNC router machines?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

CNC router machines can be of great help to your workshop and can greatly increase your productivity. Before you decide to buy it, it is necessary for you to know about it.

In this article, we will introduce you some basic knowledge of CNC wood engraving machine, also known as CNC router. CNC routers are useful when performing the same repetitive work. CNC routers often produce consistent, high-quality work and increase factory productivity. CNC routers can reduce waste, frequency of errors, and time to market for finished products.

1. What is a CNC router?

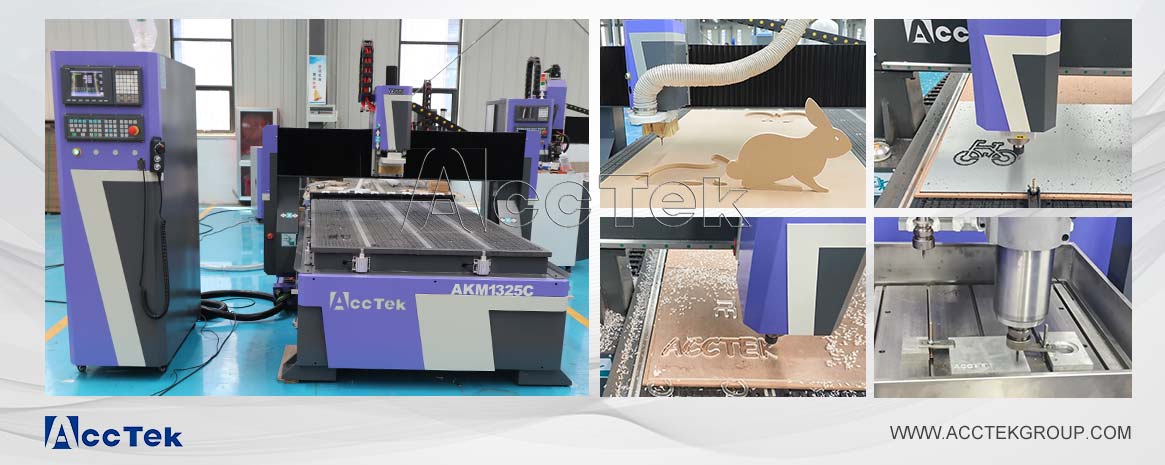

A CNC router is a CNC machine tool kit whose toolpaths can be controlled by computer numerical control. It is a computer-controlled machine for cutting a variety of hard materials such as wood, composites, aluminum, steel, plastic and foam. It is one of several tools with CNC variants. A CNC router is very similar in concept to a CNC milling machine.

CNC routers provide greater flexibility in the manufacturing process. It can be used to make many different items such as door carvings, interior and exterior decorations, planks, signs, wooden frames, moulds, musical instruments, furniture, etc. In addition, CNC routers make thermoforming of plastics easier by automating the trimming process. CNC routers help ensure part repeatability and adequate factory output.

CNC routers can process the above materials through woodworking, 3D engraving, fabrication, milling, forming, engraving, threading, grooving, and more.

CNC routers come in a variety of configurations, from small home "desktop" CNC routers to large "gantry" CNC routers used in shipbuilding facilities. While there are many configurations, most CNC routers have a few specific parts: a dedicated CNC controller, one or more spindle motors, AC inverters, drive motors and drives, T-slots or vacuum gauges, etc.

CNC routers typically come in 3-axis CNC router, 4-axis CNC router, and 5-axis CNC router formats.

As for machine size, CNC router machines are available in different sizes, as follows - and more sizes can be customized for options.

2×3ft CNC router

4×4ft CNC router

4×8ft CNC router

5×10ft CNC router

6×10ft CNC router

2. What types of CNC engraving machines are there?

Actually, from a CNC axis point of view, there are 3-axis CNC routers, 4-axis CNC routers, and 5-axis CNC routers. From the manufacturing side, one can invest in efficient industrial CNC milling machines, suitable for batch or mass production. In addition, the ATC CNC router with auto tool changer is another practical machine that is popular in sign and graphics, woodworking shops, educational training schools, and can meet production requirements of smaller sizes.

Fundamentally, there are a variety of CNC engraving machine with various functions to meet the different needs of buyers: Mainly include:

(1) Ordinary 3 axis CNC router

CNC router is a general CNC machine technology. Usually, it does not have any human-machine interface because it operates through a computer. In addition, there are 3-, 4- and 5-axis CNC routers on the market. Most routers find them useful for producing larger sized parts as well as cutting wood, plastic, sheet metal, and more.

(2) CNC router combined rotary axis device

This Rotary Unit Combo / 4 Axis Auxiliary CNC Router fits into a column. Best for engraving, flat material cutting and engraving. In addition, you can install a smaller size swivel unit on the table for column cutting.

(3) ATC CNC router

The atc cnc router has the function of auto tool change, and are mature and suitable for the manufacturing of wooden doors, cabinet doors, computer desks, furniture, mahjong tables, etc. The system adopts dual Y-axis micro-stepping.

(4) Multi-head CNC router

This series of CNC routers supports integrated control of 2-8 multi-head spindles. It can pass commands to the spindle to run in tandem. The user can set different toolpaths for multiple spindles (tools). After the first spindle completes its work, the second spindle can automatically start working.

(5) 4 axis CNC router

In a 4-axis CNC router machine, the turntable is attached to the cutting table or the spindle head can pivot in the attached plane. Its main shaft can rotate a total of 180 degrees, and it can rotate 90 degrees left and right.

(6) 5 axis CNC router

The 5 axis CNC router means that the spindle can rotate in 2 additional planes. Its main axis can be rotated 360 degrees.

The rotary axis of the 5 axis cnc router machine allows for more compact machining to deliver parts. 5 axis CNC routers come with an additional heavy-duty gantry and machine table for maximum rigidity and power to provide high-speed machining in each 5 axis CNC router.

3. How is a CNC router different from a handheld router?

Here are some tips to differentiate a CNC router from a handheld router.

(1) Fast Work Engine Frame: The CNC router uses a three-engine drive frame to move along three axes (X-Y-Z). Handheld routers are equipped with a single cutting head, as opposed to CNC routers, which can have up to five cutting heads. In this way, using CNC routers, you can deliver a large number of complex wood products.

(2) Accurate performance: Handheld routers may not convey the precision provided by their CNC counterparts. In a handheld router, an engine running at 6 to 12 amps sits on a platform that slides over the material you're cutting; it extends a bit below. These routers tend to shake and run away.

(3) SAFE & RELIABLE: CNC router machine is ideal for cutting hard surfaces, minimizing the risk of human error. It's a smart idea to perform an air cut before running a real cut. Due to the computerized nature of CNC machines, they have a wide range of preferences in woodworking activities that require the manufacture of precision objects on a large scale. They are suitable for creating deep and defined work in a short period of time.

(4) Cost-effective: High-end CNC router machines are ideal for industrial-grade applications and cost more. However, holding the router in hand can cause the router to wear out before the ideal time.

Therefore, in the long run, the maintenance cost of a handheld router will be higher than the cost of buying a high-end CNC router. Although simple and precise, it ensures that the CNC router machine requires unique training to work and is performed before the router is held in hand. As a result, CNC routers are therefore ideal in terms of cost and efficiency.

Modern CNC router machines can be of great help to your workshop and can greatly increase your productivity. Before you decide to buy it, it is necessary for you to know about it. Hope this article guide you in choosing the most suitable CNC machine!

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd