How powerful a fiber laser cutting machine do I need?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

How powerful a fiber laser cutting machine do I need? This article introduces you to several factors that affect the power of a laser cutting machine.

Today, with the continuous development of industrial production, the amount of metals used as raw materials for industrial production is huge. In order to meet the needs of efficient production of metal workpieces, fiber laser cutting machine has been continuously optimized and upgraded, becoming the mainstream equipment for metal manufacturers and metal cutting service providers.

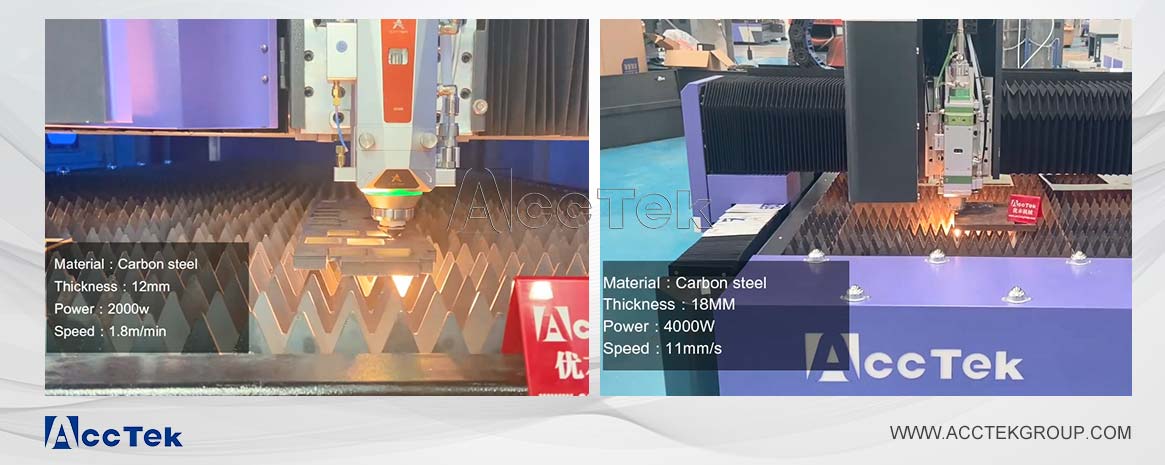

How powerful a fiber laser cutting machine do I need? Some client always have this confusion before buying a fiber laser cutting machine. It is very normal. What determines your power choice is the thickness of the cut sheet. The thicker the plate, the more difficult cutting, the greater the power required.

Different materials and different thicknesses require different power fiber laser cutting machines. If you want to choose the most suitable laser power for your work. It is very necessary tell the laser cutting machine supplier what will you mainly do, what the max thickness will cut by this machine? Then professional supplier will provide professional suggestion and most suitable power for your work.

Firstly ,You should tell the laser cutting machine supplier what will you do by this machine. In another word, what’s the main material will cut by this fiber laser cutting machine. Secondly, you should tell supplier what’s the max thickness will cut by this machine. These two question is the basic which can help you and supplier choose a right laser power for your work.

Different power laser cutting machine has the different speed when cutting, if the same thickness material, but you would like to achieve the high speed, no burns and better cutting effect, the bigger power is necessary. But there is another question, only tell the laser cutting machine supplier the material and max thickness is not enough. What else should be paid attention to when choose a right power cnc laser cutting machine? As we know, different power metal laser cutting machine has the restrict cutting ability, normal cutting ability and high speed cutting ability.

For example, some client tell us they want to cut max 10mm stainless steel. According to the cutting ability of the laser power, it need 3000W or 4000W laser cutting machine. 3000W fiber laser cutting machine for stainless steel restrict cutting ability is the 10mm, but if client will process this thickness in bulk, it need at least 4000W laser power.

Generally In this situation, we will also ask what’s the common thickness will cut ? Do you often to cut 10mm metal? According to our experiences, some client maybe often to cut just 1mm or 2mm metal, but just occasionally cut 10mm once or twice each year, even won’t to cut. So if we just according to the max thickness to recommend the metal laser cutting machine power, but don’t often to cut 10mm. From the perspective of maximizing resource utilization and helping customers save costs, choose the 3-4kw laser cutting machine is a big resource waste.

Therefore how powerful a metal laser cutting machine should be choose, it is not only according to the material and max thickness, common thickness. But also should considering the speed, cutting effect, if you would like to processing in bulk or not. Only in this ,we can recommend the most suitable laser power for the client.

1) Long lifetime; excellent beam quality; precision and smooth cutting edge.

2) Fast metal cutting speed. It's three times quicker than CO2 laser cutting machine.

3) High conversion rate between laser and electricity (as high as 30%); low electricity consumption. low operation costs. It's flexible transmission. It does not require working gas, which saves operation costs.

4) High stability and precision, metal laser cutting machine uses heavy duty frame.

5) Powerful functions. It's equipped with professional CNC metal cutting software, which supports AI, DXF, PLT, GBX files. It boasts below functions, including bridge connection, leapfrog, slotting compensation, etc.

CNC laser cutting machines are widely used in the field of metal cutting due to their excellent performance such as fast speed, high efficiency, high quality and high yield. Extensive functions and precise cutting make the fiber laser cutting machine fully meet the requirements of metal manufacturers. Numerous facts have proved that the fiber laser cutting machine is faster and more precise in the process of cutting sheet metal. By choosing the right cnc laser cutting machine and setting the correct parameters, you can cut the sheet metal workpiece at one time, and achieve the good effect of no burr and no slag on the cutting section.

For the fiber laser cutting machine application is very variety and widely. The fiber laser cutting machine is suitable for metal cutting like stainless steel sheet, mild steel plate, carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper sheet, brass sheet, bronze plate, old plate, silver plate, titanium plate, metal sheet, metal plate, etc.

This metal laser cutting machine is widely used in manufacture billboard, advertising, signs, signage, metal letters, led letters, kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, etc.

Whether you are laser cutting carbon steel, laser cutting stainless steel, or laser cutting aluminum, iron, cooper etc. safety is always first and foremost. Users need to participate in fiber laser metal cutting machine operation training, master the relevant knowledge of operating the machine, and be able to correctly start the machine and operate the machine according to the laser cutting machine startup procedure. In addition to this, the operator and others in the laser cutting workplace are required to wear laser safety glasses. Laser cutting is safe, but the emitted laser beam can cause certain damage to the retina and cornea, so laser protection is very important for your eyes.

Communication is most important factor for human interaction, good communication is the basis for effective work, it can help client and us make the smooth business, avoid misunderstanding and error as well. Whatever for the client and laser cutting machine supplier, we should communicate much before make deal in advance.

Factors affecting the power of fiber laser cutting machine

How powerful a fiber laser cutting machine do I need? Some client always have this confusion before buying a fiber laser cutting machine. It is very normal. What determines your power choice is the thickness of the cut sheet. The thicker the plate, the more difficult cutting, the greater the power required.

Different materials and different thicknesses require different power fiber laser cutting machines. If you want to choose the most suitable laser power for your work. It is very necessary tell the laser cutting machine supplier what will you mainly do, what the max thickness will cut by this machine? Then professional supplier will provide professional suggestion and most suitable power for your work.

Firstly ,You should tell the laser cutting machine supplier what will you do by this machine. In another word, what’s the main material will cut by this fiber laser cutting machine. Secondly, you should tell supplier what’s the max thickness will cut by this machine. These two question is the basic which can help you and supplier choose a right laser power for your work.

Different power laser cutting machine has the different speed when cutting, if the same thickness material, but you would like to achieve the high speed, no burns and better cutting effect, the bigger power is necessary. But there is another question, only tell the laser cutting machine supplier the material and max thickness is not enough. What else should be paid attention to when choose a right power cnc laser cutting machine? As we know, different power metal laser cutting machine has the restrict cutting ability, normal cutting ability and high speed cutting ability.

For example, some client tell us they want to cut max 10mm stainless steel. According to the cutting ability of the laser power, it need 3000W or 4000W laser cutting machine. 3000W fiber laser cutting machine for stainless steel restrict cutting ability is the 10mm, but if client will process this thickness in bulk, it need at least 4000W laser power.

Generally In this situation, we will also ask what’s the common thickness will cut ? Do you often to cut 10mm metal? According to our experiences, some client maybe often to cut just 1mm or 2mm metal, but just occasionally cut 10mm once or twice each year, even won’t to cut. So if we just according to the max thickness to recommend the metal laser cutting machine power, but don’t often to cut 10mm. From the perspective of maximizing resource utilization and helping customers save costs, choose the 3-4kw laser cutting machine is a big resource waste.

Therefore how powerful a metal laser cutting machine should be choose, it is not only according to the material and max thickness, common thickness. But also should considering the speed, cutting effect, if you would like to processing in bulk or not. Only in this ,we can recommend the most suitable laser power for the client.

Main features of the fiber laser cutting machine.

1) Long lifetime; excellent beam quality; precision and smooth cutting edge.

2) Fast metal cutting speed. It's three times quicker than CO2 laser cutting machine.

3) High conversion rate between laser and electricity (as high as 30%); low electricity consumption. low operation costs. It's flexible transmission. It does not require working gas, which saves operation costs.

4) High stability and precision, metal laser cutting machine uses heavy duty frame.

5) Powerful functions. It's equipped with professional CNC metal cutting software, which supports AI, DXF, PLT, GBX files. It boasts below functions, including bridge connection, leapfrog, slotting compensation, etc.

CNC laser cutting machines are widely used in the field of metal cutting due to their excellent performance such as fast speed, high efficiency, high quality and high yield. Extensive functions and precise cutting make the fiber laser cutting machine fully meet the requirements of metal manufacturers. Numerous facts have proved that the fiber laser cutting machine is faster and more precise in the process of cutting sheet metal. By choosing the right cnc laser cutting machine and setting the correct parameters, you can cut the sheet metal workpiece at one time, and achieve the good effect of no burr and no slag on the cutting section.

For the fiber laser cutting machine application is very variety and widely. The fiber laser cutting machine is suitable for metal cutting like stainless steel sheet, mild steel plate, carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper sheet, brass sheet, bronze plate, old plate, silver plate, titanium plate, metal sheet, metal plate, etc.

This metal laser cutting machine is widely used in manufacture billboard, advertising, signs, signage, metal letters, led letters, kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, etc.

Whether you are laser cutting carbon steel, laser cutting stainless steel, or laser cutting aluminum, iron, cooper etc. safety is always first and foremost. Users need to participate in fiber laser metal cutting machine operation training, master the relevant knowledge of operating the machine, and be able to correctly start the machine and operate the machine according to the laser cutting machine startup procedure. In addition to this, the operator and others in the laser cutting workplace are required to wear laser safety glasses. Laser cutting is safe, but the emitted laser beam can cause certain damage to the retina and cornea, so laser protection is very important for your eyes.

Communication is most important factor for human interaction, good communication is the basis for effective work, it can help client and us make the smooth business, avoid misunderstanding and error as well. Whatever for the client and laser cutting machine supplier, we should communicate much before make deal in advance.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd