Can the laser cleaning machine clean aluminum

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

Aluminum alloy, as a common industrial raw material, needs to be cleaned when there is contamination on the surface. So can the laser cleaning machine clean aluminum? What is the effect?

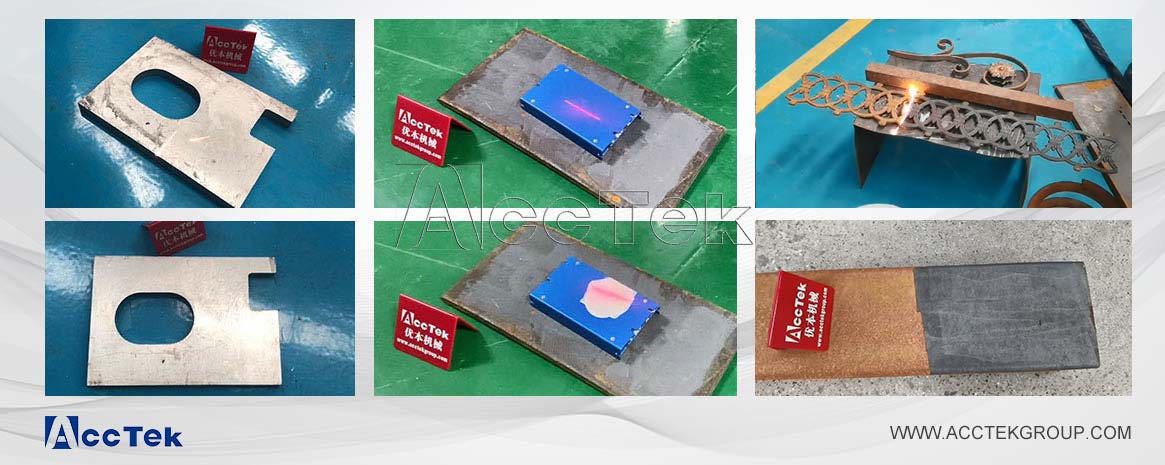

Aluminum alloys are widely used in the field of metal manufacturing due to their high strength, good toughness and excellent processing performance, such as automotive parts, aluminum alloy doors and windows, guardrails and other industrial projects. Many finished products produced by these aluminum materials need to be used outdoors, and when they are exposed to moisture and oxygen in the air for a long time, it is very easy to react to form a gray oxide layer on the surface of the material, which we also call aluminum rust. So how can this aluminum rust be removed? The laser cleaning machine can achieve non-destructive and efficient cleaning to a certain extent.

Before laser technology was used in the cleaning field, aluminum rust was usually processed by some traditional cleaning methods. First, use chemical agents for melting reaction, and then use some mechanical tools to rub. These two methods can achieve certain results, but the damage to the workpiece during the cleaning process is also very large. Moreover, these two methods may also be unclean for some long-term aluminum rust. The advent of laser rust removal machine has completely changed this problem. Using laser to clean aluminum can not only obtain a clean surface of the material, but also achieve non-destructive cleaning without causing damage to the workpiece.

In addition to laser rust removal, it can also laser remove oil stains. After absorbing the focused laser energy, the oil on the aluminum surface can evaporate or peel off instantly.

2. Safety and environmental protection. Laser rust removal does not require other media such as chemicals, and will not cause environmental pollution. On the one hand, it is more environmentally friendly and meets the needs of social development; on the other hand, it also means that it will not harm the health of laser cleaning machine operators and is safer.

3. The cleaning speed is faster and more efficient. Laser rust remover is much faster than using chemicals, and it can be used directly after cleaning without waiting for drying.

4. Low operating cost and more cost-effective. The laser rust removal machine does not need to use a lot of consumables, it can be used when it is powered on, and the cost is very low. Moreover, the laser cleaning machine is easy to operate and can be used by ordinary workers after short-term training. One person can complete multiple metal cleaning projects. This can reduce labor costs for companies to recruit high-skilled workers.

5. Laser rust removal, laser oil removal effect is more fine. Thanks to the selective and positionable laser beam, even very small corners or workpieces with complex designs can be positioned for cleaning. The final product after laser cleaning is much finer than other cleaning methods.

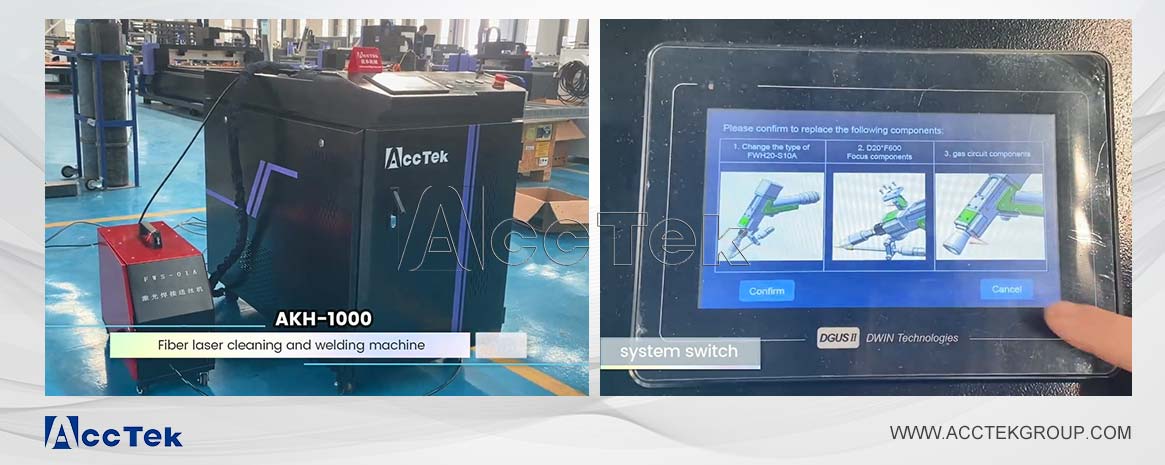

At present, many laser cleaning machine manufacturers provide fiber welder cleaning machine, which means that one machine has two functions of laser cleaning and laser welding. You can use a laser cleaning system to treat the material prior to sheet metal welding to remove oxides and other contaminants, which can strengthen the weld and increase the stability of the weld. Then, you can switch the fiber welder cleaning machine from the laser cleaning system to the laser welding system to start the welding work. After the welding is finished, use the cleaning system again to clean the weld seam to achieve the aesthetic effect of the finished product.

Through the analysis of this article, we know that laser cleaning aluminum has good results. Of course, in addition to the application in the aluminum industry, the laser rust remover is also widely used in other different fields. Any metal that needs rust and oil removal can be removed by laser cleaning. Of course, different types of laser cleaning machines target different industries, and the power and generator type of the laser cleaning machine will affect the cleaning effect. Therefore, before you buy a laser cleaning machine, you need to describe your specific needs in detail to the laser cleaning machine manufacturer in order to obtain professional guidance.

Before laser technology was used in the cleaning field, aluminum rust was usually processed by some traditional cleaning methods. First, use chemical agents for melting reaction, and then use some mechanical tools to rub. These two methods can achieve certain results, but the damage to the workpiece during the cleaning process is also very large. Moreover, these two methods may also be unclean for some long-term aluminum rust. The advent of laser rust removal machine has completely changed this problem. Using laser to clean aluminum can not only obtain a clean surface of the material, but also achieve non-destructive cleaning without causing damage to the workpiece.

How laser clean aluminum

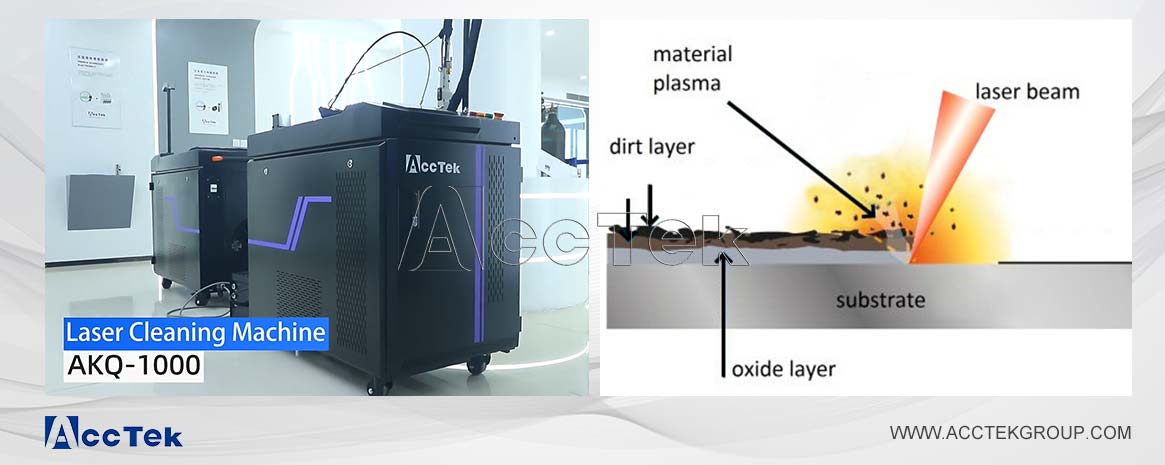

The aluminum laser rust remover uses a high-energy laser beam to irradiate the surface of the object. After the aluminum rust on the surface of the workpiece absorbs the laser energy, it will expand and contract, and the aluminum rust on the surface will be loosened. Vibration will directly smash the detached aluminum rust.In addition to laser rust removal, it can also laser remove oil stains. After absorbing the focused laser energy, the oil on the aluminum surface can evaporate or peel off instantly.

What are the advantages of laser cleaning aluminum

1. No damage cleaning. The laser cleaning machine does not touch the surface of the aluminum material during operation, so the non-contact processing will not damage the material of the aluminum material itself.2. Safety and environmental protection. Laser rust removal does not require other media such as chemicals, and will not cause environmental pollution. On the one hand, it is more environmentally friendly and meets the needs of social development; on the other hand, it also means that it will not harm the health of laser cleaning machine operators and is safer.

3. The cleaning speed is faster and more efficient. Laser rust remover is much faster than using chemicals, and it can be used directly after cleaning without waiting for drying.

4. Low operating cost and more cost-effective. The laser rust removal machine does not need to use a lot of consumables, it can be used when it is powered on, and the cost is very low. Moreover, the laser cleaning machine is easy to operate and can be used by ordinary workers after short-term training. One person can complete multiple metal cleaning projects. This can reduce labor costs for companies to recruit high-skilled workers.

5. Laser rust removal, laser oil removal effect is more fine. Thanks to the selective and positionable laser beam, even very small corners or workpieces with complex designs can be positioned for cleaning. The final product after laser cleaning is much finer than other cleaning methods.

Application of laser cleaning machine in welding industry

In addition to the good effect of cleaning the aluminum rust, the laser cleaning machine also plays an important role in the cleaning of the welding seam after aluminum welding. After the welding of aluminum alloy materials, a layer of black ash with uneven thickness is sometimes covered near the surface of the weld. If the treatment is not clean, it will affect the quality of the subsequent process and the beauty of the cost. The use of a laser cleaning machine can solve this problem very well.At present, many laser cleaning machine manufacturers provide fiber welder cleaning machine, which means that one machine has two functions of laser cleaning and laser welding. You can use a laser cleaning system to treat the material prior to sheet metal welding to remove oxides and other contaminants, which can strengthen the weld and increase the stability of the weld. Then, you can switch the fiber welder cleaning machine from the laser cleaning system to the laser welding system to start the welding work. After the welding is finished, use the cleaning system again to clean the weld seam to achieve the aesthetic effect of the finished product.

Through the analysis of this article, we know that laser cleaning aluminum has good results. Of course, in addition to the application in the aluminum industry, the laser rust remover is also widely used in other different fields. Any metal that needs rust and oil removal can be removed by laser cleaning. Of course, different types of laser cleaning machines target different industries, and the power and generator type of the laser cleaning machine will affect the cleaning effect. Therefore, before you buy a laser cleaning machine, you need to describe your specific needs in detail to the laser cleaning machine manufacturer in order to obtain professional guidance.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd