Why choose a handheld laser welding machine

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

Handheld laser welding machine is an emerging metal welding equipment, why it has been chosen by more and more customers since its appearance.

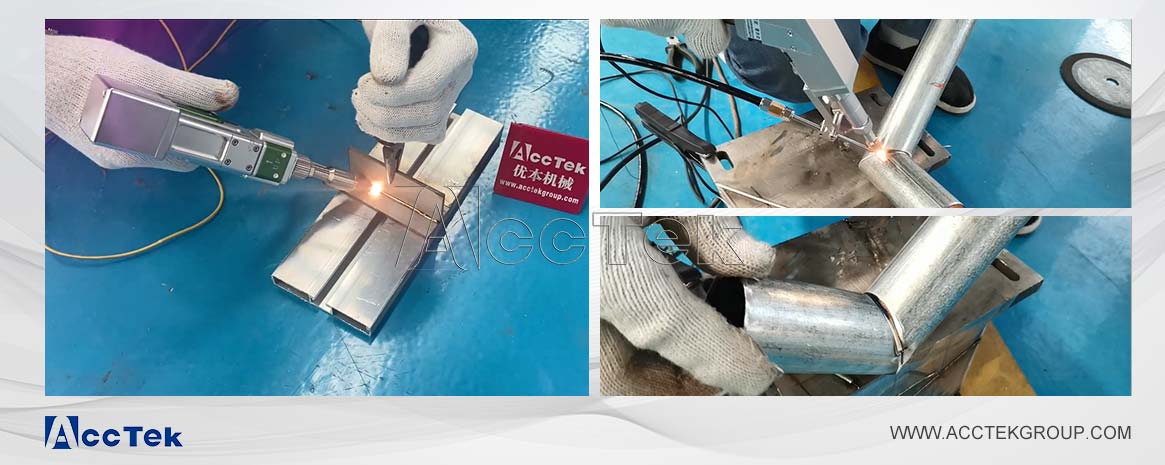

Handheld laser welding machine is an emerging technology metal welding equipment, its appearance makes up for the blank of handheld welding in the laser equipment industry. By using a handheld laser welding gun to replace the previous fixed optical path, the operation is convenient and the welding is sensitive. These advantages make the laser welding machine gradually replace the traditional metal welding form and become the mainstream equipment in the welding market. The working principle of laser welding is to directly irradiate a high-energy laser beam on the surface of the metal material, and through the interaction between the laser and the material, the material is condensed inside, and then cooled to form a weld.

The handheld laser welding machine can overcome the limitation of the travel space of the worktable, and the welding depth is large and the melting is sufficient. It can not only complete thermal conduction welding, but also complete continuous deep penetration welding, spot welding, butt welding, stitch welding and other welding processes. You can use the handheld laser welding gun not only to weld metal, but also to complete less demanding metal cutting work. You only need to replace the welding copper nozzle with the cutting copper nozzle, which is very convenient.

At present, the fiber laser welding machine can completely replace various traditional welding equipment such as argon arc welding and electric welding in the welding of thin stainless steel plates, iron plates, galvanized plates and other metal materials. And because the laser has more accurate positioning, for some special products that are difficult to access by traditional welding, the hand-held laser welding machine can be effectively used to complete the welding work.

As a professional laser welding machine manufacturer, ACCTEK LASER provides users with handheld welding equipment with various laser power ranges from 1000W to 3000W. They have a variety of laser welding guns and laser welding systems to choose from, different configurations have different functions, which can be customized according to your actual needs. Each fiber laser welding machine can weld both metal plates and metal pipes, and has a wide range of welding scene applications.

The handheld laser welding machine has become a metal welding equipment that is widely used by many large and small enterprises. And with the continuous development of laser technology and the improvement of the capabilities of laser welding machine manufacturers, fiber laser welding machines will continue to innovate in various functions. It is believed that in the future, it will provide more favorable support for the development of the industry.

Why choose a handheld laser welding machine

Various welding methods

The handheld laser welding machine can overcome the limitation of the travel space of the worktable, and the welding depth is large and the melting is sufficient. It can not only complete thermal conduction welding, but also complete continuous deep penetration welding, spot welding, butt welding, stitch welding and other welding processes. You can use the handheld laser welding gun not only to weld metal, but also to complete less demanding metal cutting work. You only need to replace the welding copper nozzle with the cutting copper nozzle, which is very convenient.Easy to operate laser welding system

The laser welding system is equipped with a smart touch screen, with more than a dozen different languages that can be flexibly switched. A good human-computer interface provides a user-friendly operating experience. The professional laser welding system provides users with process parameters of various welding methods. In addition, users can save commonly used process parameters in the process library. When the same welding process is performed next time, the user can directly select the parameters that have been saved without wasting time for setting, and the whole welding process is very convenient.Easy to move, suitable for various welding scenarios

Handheld laser welding machine is a small welding equipment composed of fiber laser, laser welding gun and laser welding system. Lightweight universal wheels are installed at the bottom of the cabinet, you can easily carry the laser welding machine to any work scene where welding needs are required, which also makes it possible to operate metal welding outdoors. In addition, the connecting cable between the hand-held laser welding gun and the machine is 10 meters long, which means that you can overcome the limitations of the workbench space and complete long-distance welding operations without moving the fiber laser welding machine.Laser welding metal works well

Compared with traditional welding processes, handheld laser welding has higher energy density and can achieve better welding results. In addition, the heat effect of the laser welding area is small, and the material welding place is not prone to problems such as deformation, blackening, and traces. After the traditional welding metal process is finished, in order to ensure that the weld is smooth and not rough, manual grinding is usually required. The hand-held laser welding shows more advantages in the processing effect: continuous welding, smoother welds, and less need for subsequent grinding.Laser welded metal costs less

On the one hand, in terms of processing cost, the processing cost of laser welding system can be reduced by about 30% compared with arc welding. On the other hand, the use of laser welding machines is simple and easy to learn, and the technical requirements for operators are not high. Ordinary workers can be employed after a short training period, and one person can complete multiple welding projects. Therefore, it saves the workshop's demand for high-tech welding talents.Fiber laser welding machine is safer

The laser welding system can monitor the running status of the machine in real time, monitor and collect the running status of the laser, chiller, and control panel. Once an abnormality occurs, the user can cut off the operation of the machine in time through the alarm device. Moreover, the welding tip is only effective when the switch is touched when it touches the metal, and the light is automatically locked after the workpiece is removed. This safety lock device can prevent the laser from accidentally injuring the staff.At present, the fiber laser welding machine can completely replace various traditional welding equipment such as argon arc welding and electric welding in the welding of thin stainless steel plates, iron plates, galvanized plates and other metal materials. And because the laser has more accurate positioning, for some special products that are difficult to access by traditional welding, the hand-held laser welding machine can be effectively used to complete the welding work.

As a professional laser welding machine manufacturer, ACCTEK LASER provides users with handheld welding equipment with various laser power ranges from 1000W to 3000W. They have a variety of laser welding guns and laser welding systems to choose from, different configurations have different functions, which can be customized according to your actual needs. Each fiber laser welding machine can weld both metal plates and metal pipes, and has a wide range of welding scene applications.

The handheld laser welding machine has become a metal welding equipment that is widely used by many large and small enterprises. And with the continuous development of laser technology and the improvement of the capabilities of laser welding machine manufacturers, fiber laser welding machines will continue to innovate in various functions. It is believed that in the future, it will provide more favorable support for the development of the industry.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd