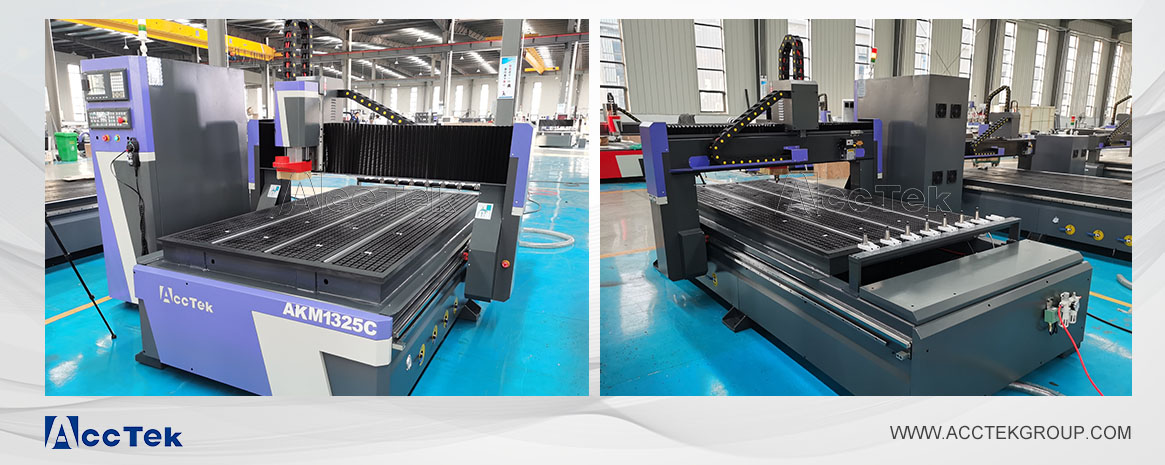

Affordable Linear ATC CNC Router with Automatic Tool Changer

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

This 4×8 ATC CNC router machine is a high-quality, large-table CNC engraving equipment with automatic tool change function, which can complete a series of processes such as engraving, cutting, milling, grooving, and hollowing out.

ATC CNC router machine is an advanced computer-controlled CNC engraving equipment. Compared with ordinary CNC router machines, ATC CNC router machines have automatic tool changers and independent tool magazines. Therefore, the ATC CNC router machine can automatically change the tool through the computer program without stopping the engraving and cutting process. ATC CNC woodworking machine greatly improves work efficiency and is ideal for mass production.

This 4×8 ATC CNC router machine is a high-quality, large-table CNC engraving equipment with automatic tool change function, which can automatically complete a series of processes such as engraving, cutting, milling, grooving, and hollowing out. The linear auto tool changer is loaded with 8 different CNC drill bits. When the machine engraves complex patterns, it can automatically grab the tool according to the program, without the need to manually change the drill bit, and the tool change speed only takes a few seconds.

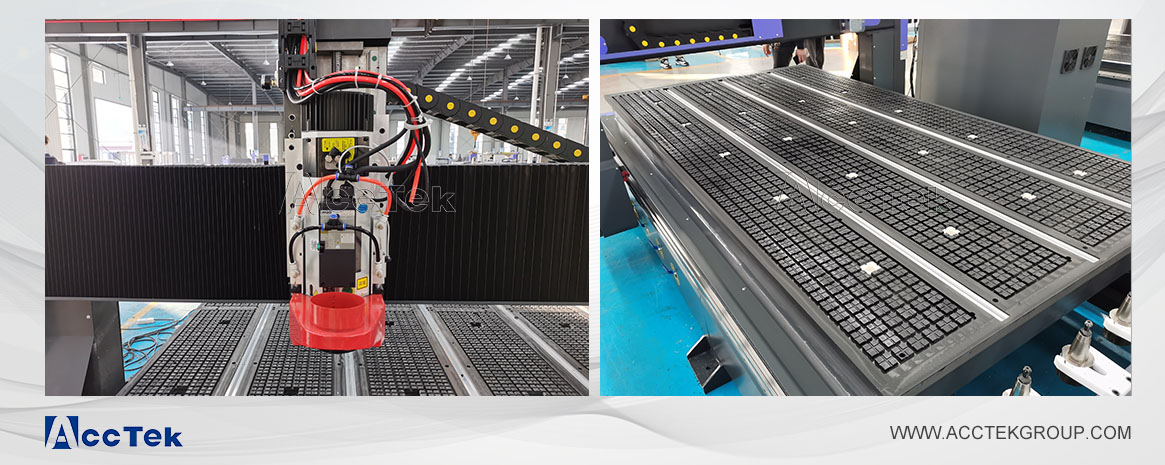

The ATC spindle adopts HQD, a well-known Chinese brand that has obtained CE certification. The 9.0KW high-power air-cooled spindle has strong cutting ability, good starting performance and large torque, which can give full play to the advantages of high speed and high efficiency of the machine tool. So that the ATC CNC router machine can easily complete the processing needs of the plate, and has higher engraving accuracy. In addition to the HQD spindle, there is also the Italian brand HSD to choose from.

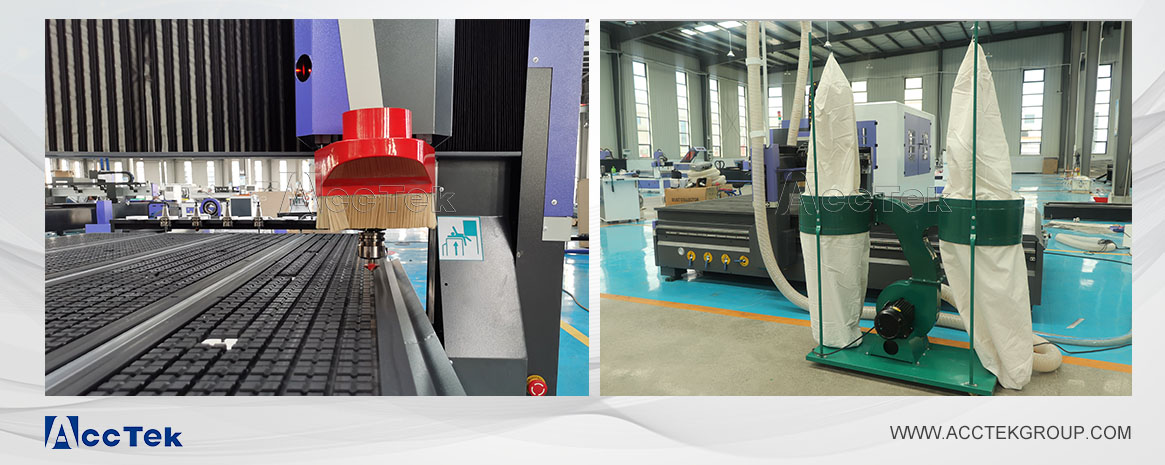

ATC CNC router machines all use T-slots and vacuum combined worktables, which are more conducive to the processing of different materials and are very helpful to improve work efficiency. The T-slot workbench can fix small-sized materials or hollowed-out plates with clips; the vacuum table can fix large-sized materials or irregular plates through strong adsorption, making processing more convenient, simple and efficient. The workbench of the 4×8 CNC router machine is usually divided into four areas, each area is controlled by a switch, which can be used flexibly according to the size of the material to be processed.

The system of ATC CNC router machine can choose Mach3 control system or Syntec control system according to the budget. Support offline operation, no need to reset from scratch even if the power is suddenly cut off. The machine is equipped with Taiwan Hiwin linear guide, the transmission is stable and precise, which ensures that the machine has higher processing accuracy. High-sensitivity tool sensor makes the tool position more precise.

Servo motor and driver make ATC CNC router machine run more smoothly. ACCTEK has Leadshine Easy Servo, Delta Servo and Yaskawa Servo Motor to choose from. Another feature of the machine is the function of automatic oil lubrication, only need to set the interval time and oiling time, the machine can automatically lubricate the guide rail and lead screw according to the settings.

In order to maintain the cleanliness of the working environment, the ATC CNC router machine is also equipped with a double-bag dust collector. You can see that a dust brush is installed under the spindle, and the dust such as wood chips is controlled in a small area by the dust brush, and then the sundries are sucked into the dust collector. This can effectively reduce the spread of wood chips in the workshop and maintain a good working environment.

Application of ATC CNC router machine with automatic tool changer:

1. Furniture industry: processing various doors, windows, cabinets, craft wooden doors, screens and other furniture.

2. Advertising industry: various signs, license plates, advertising decoration and other promotional materials.

3. Crafts: Carve any text and graphics on gifts and souvenirs.

4. All kinds of non-metallic materials such as wood, aluminum plate, plastic, MDF, corrugated board, PVC, acrylic, etc.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd