Italian user order 2000W Fiber Laser Cutting Machine

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

To improve workshop efficiency and metal cutting quality, an Italian customer ordered a 2000W fiber laser cutting machine at ACCTEK.

With the development of the manufacturing industry, the quality requirements for metal workpieces are getting higher and higher. Compared with traditional metal cutting process, fiber laser cutting machine has obvious advantages. Laser cutting adopts a non-contact method, which will not deform the metal workpiece, and has high cutting accuracy, which can obtain more accurate metal parts.

Some time ago, an Italian user contacted us. In order to improve workshop efficiency and metal cutting quality, he ordered a 2000W fiber laser cutting machine from ACCTEK. Now the laser cutting machine has been tested and is ready to be shipped to Italy.

The working area of the fiber laser cutting machine AKJ1530F is 1500×3000mm. The heavy-duty frame is adopted, the rectangular tube wall thickness of the body is 10mm, and the body weight is 3500KG. It is the strongest frame in China's CNC machine tool industry. It can increase the stability of the guide rail, effectively avoid the deformation of the bed, and the service life can be as long as 25 years.

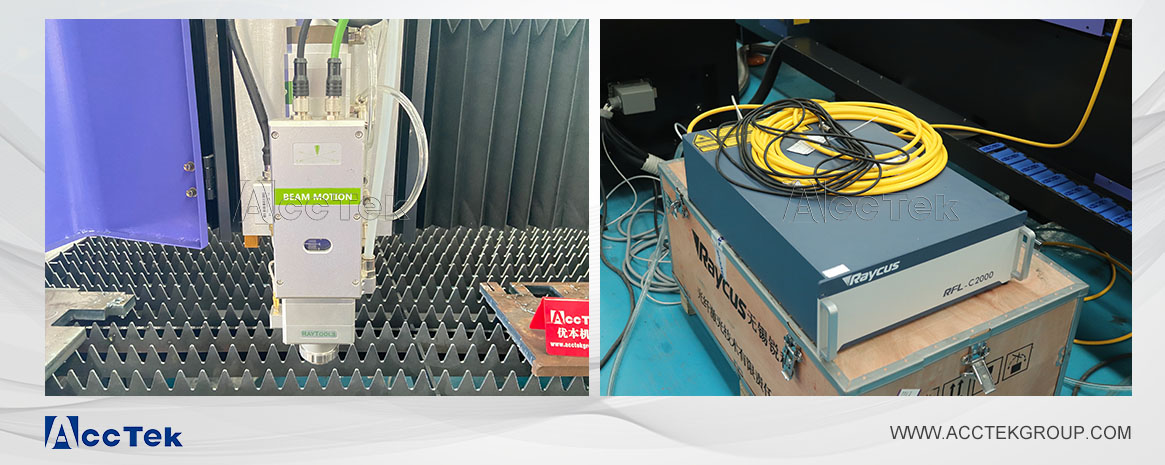

This 2000W laser metal cutting machine adopts Raytools auto-focus cutting head, which can perform high-speed perforation cutting of various metal materials with a repeatability of 0.01mm. Automatically find the best focal length instead of manual focus, the adjustment range is -10-+10mm, and the focusing speed reaches 400mm/s, which is more efficient. IP65 dustproof design, fully protect the internal optical components and prolong the service life. Built-in collimating lens focusing lens double water cooling structure, reduce the temperature of the cutting head and prolong the service life of the cutting head.

The Italian user chose the Raycus laser generator for his fiber laser cutting machine, and the stable optical quality ensures a finer cutting effect when cutting thick plates. Equipped with high-power Yaskawa servo motor to ensure high-speed and smooth operation of the laser cutting machine. Yaskawa absolute AC servo drive system greatly shortens the settling time, realizes high-speed acceleration and deceleration, and has a fast response speed.

Laser metal cutting machine AKJ1530F adopts Cypcut FSCUT2000C controller system, which provides fine cutting technology, smooth start and end in the cutting of tool path. It supports advanced functions such as finding workpiece edges, automatic focus control, double shuttle, breakpoint positioning, QR code generation, and residual material segmentation, especially suitable for high-speed and high-precision laser cutting.

Fiber laser cutting machines have irreplaceable advantages in the metal manufacturing industry. Choosing a laser metal cutting equipment for the workshop plays an important role in promoting the development of enterprises. It is believed that Italian user can gain more business and a larger market with the help of fiber laser cutting machine AKJ1530F.

ACCTEK has a reduced price sale for 2000W fiber laser cutting machines from March 1 to June 30. Among them, the fiber laser cutting machine equipped with 2000W JPT laser generator is 1500 US dollars lower than the original price. That is to say, the cheapest 2000W fiber laser cutting machine can be purchased for only $23,100, and the lowest price is only available during the promotion.

Communicate online now, and you can buy a high-efficiency fiber laser cutting machine at an affordable price.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd