The advantages of laser welding machine for metal tube

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

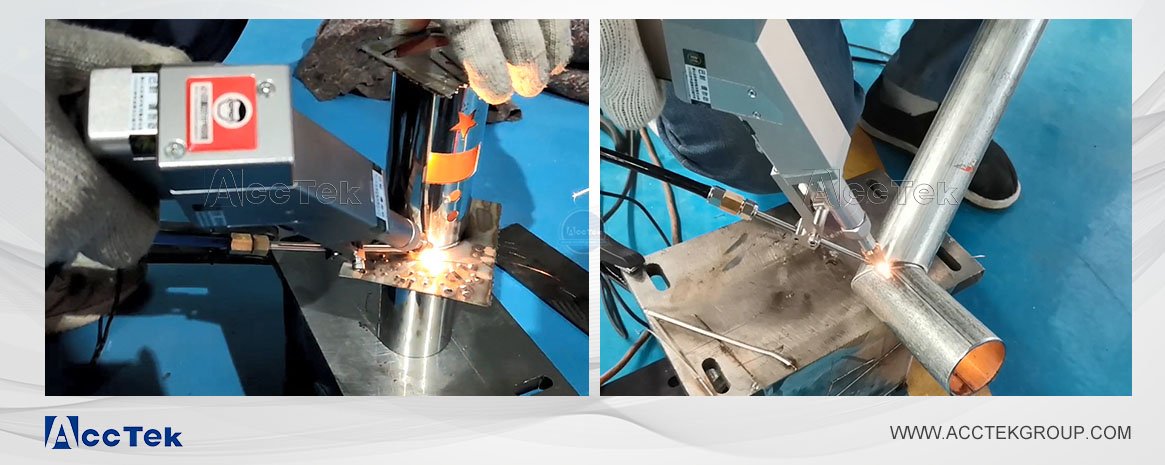

Fiber laser welding machine has unique properties for welding various metal tubes and are a versatile and efficient method of joining metal tubes.

The emergence of laser welding technology is a technological change in industrial welding. Fiber laser welding machine is based on professional welding system and CNC technology, which makes laser welding easier to use. Laser welding has unique properties for welding a variety of metal tubes, making it an ideal and applicable process for many metal fabricators.

The laser welding process creates a molten pool between two metal surfaces that solidifies within milliseconds to form a weldment. Welding is required for the molding of automobile exhaust tubes, fitness equipment, swimming pool stairs, and various tubes. Laser welding technology is a versatile and cost-effective method of joining metal tubes. The precise control of laser welding machines offers users several advantages compared to traditional welding methods.

Faster welding speed: Laser welding is a very fast technology. Depending on the type and power of the laser used, the connection between metal tubes can be done at speeds of several meters per minute.

Weld strength: The laser weld is narrow, the aspect ratio is good, and the strength is higher.

Heat-Affected Zone: The average heat input provided by the laser welding process is low, so the heat-affected zone is limited.

Precision work: Small, tightly controlled laser beams allow precise micro-welding of tiny components.

Deformation: The part has minimal deformation or shrinkage.

No contact: There is no physical contact between the material and the laser head, which will not cause damage to the parts of the laser welding machine.

Scrap: Laser welding is controllable and produces a small amount of scrap.

Works with all kinds of metal materials: Using the laser, many different materials can be welded or joined, including steel, stainless steel, aluminum, titanium and nickel alloys.

ACCTEK fiber laser welding machine adopts hand-held welding head, which is light in weight, small in size, ergonomically designed and comfortable to hold. The connection cable between the machine and the welding gun is up to 10m, which can easily complete the welding work of metal tube projects in the workshop without moving the machine. The laser welding can choose from 1000W, 1500W and 2000W of laser power. The high-power laser source ensures faster welding, no marks, no discoloration, and no post-polishing required.

ACCTEK handheld laser welding machines excel in welding a wide variety of metal tubes. This metal welding machine is easy to operate and requires little practice to use. The welded product is smooth and beautiful, no subsequent grinding is required, and the welding speed is very fast, which can save you a lot of time.

Numerous facts have proven that laser welding is a superior process. Laser welding machines are becoming more and more popular in the field of industrial welding as the welding equipment with the highest return on investment. To learn more about laser welding effects, you can get laser welding videos online.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd