The Best Buying Guide for Laser Welding Machine in 2022

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

If you are buying a laser welding machine for the first time, it is necessary to know some getting started tips. When choosing a laser welding machine, you can consider the following aspects.

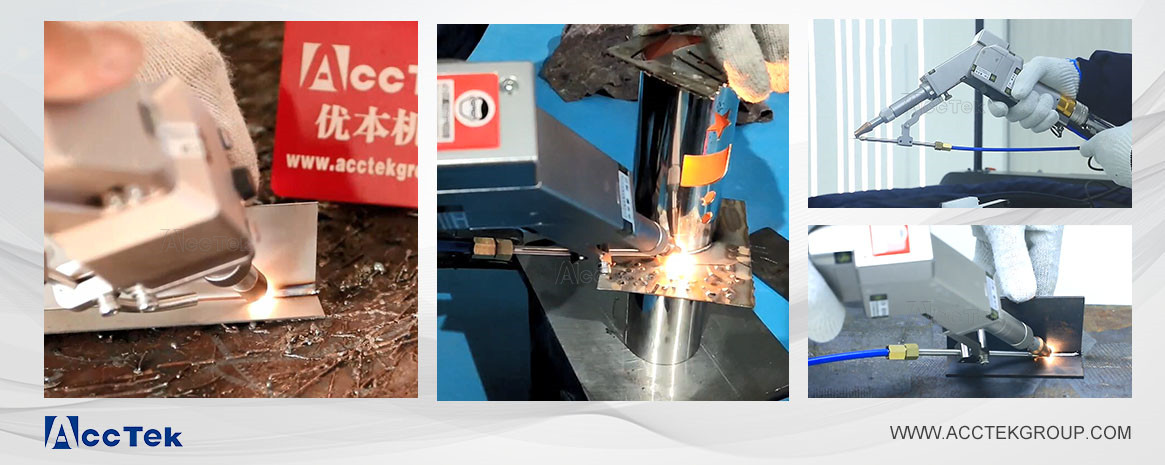

With the development and maturity of laser technology, laser welding machines are widely used in many industries. Laser welding is a brand new welding method, and can realize place welding, butt welding, stick welding, seal welding, etc. It has a high depth to width ratio, small weld size, little heat influenced area, tiny deformation, and fast welding speed.

If you are buying a laser welding machine for the first time, it is necessary to know some getting started tips. When choosing a laser welding machine, you can consider the following aspects.

1. How to choose the laser type

Your laser welding machine can be equipped with one of two types of lasers: pulsed or continuous. Which one to choose depends on the thickness of the material you are welding.

Pulsed lasers work on thin and light metals, preventing them from deforming or melting. This type of laser welding machine is mainly used for welding sheet metal, razor blades, gold jewelry links and other materials.

Continuous lasers are mainly used for welding thick metal workpieces, and they are particularly effective for refractory metals. If you use this type of laser welding machine on a part that is too thin, it can cause damage to the part.

2. How to choose the power of the laser welding machine

The laser generator is the core of the laser equipment. Generally speaking, the higher the power of the laser welding machine, the deeper the welding depth will be. For example. If the welding depth is required to be 0.5mm-3mm, then a 1000W laser welding machine can meet the demand. But it should be noted that if it is penetration welding or spot welding, you can choose a 1000W laser welding machine; if it is continuous welding, it is better to use a laser with a higher power. It is more appropriate to choose a 1500W or 2000W laser welding machine.

If you are not sure which power laser welding machine to use, you can consult online and ACCTEK staff will help you.

3. How to choose the configuration of laser welding

The configuration of laser welding machine involves many aspects, and the configuration of laser welding machine for different purposes is different. For example, mold welding of welding molds, jewelry welding of welding jewelry, optical fiber transmission laser welding machines, etc., the price naturally varies from equipment to equipment. When purchasing a laser welding machine, you should choose the right machine according to your product type, processing technology and processing requirements.

4. How to choose the best laser welding machine supplier

First of all, it is necessary to judge whether it is a professional laser equipment manufacturer, so as to fully guarantee the quality of the machine. Secondly, the after-sales service of the laser welding machine provider is also very important. ACCTEKLASER provides free technical support and training. During the process of using the machine, we will answer technical questions for you at any time and help you quickly become an experienced laser welding machine operator.

ACCTEK laser welding machines are on sale at reduced prices from January 15th to February 15th. Each laser welding machine is $500 off its original price. That is to say, the cheapest laser welding machine can be purchased for $6,900, and the lowest price is only available during the event. There are only five days left to buy the cheapest laser welding machine now, if you are choosing welding equipment, you can learn more on ACCTEK official website.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd