What are the core components of a fiber laser cutting machine

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

Fiber laser cutting machine is widely used in metal cuttinging projects. If you disassemble a fiber laser cutting machine, what are the key core components?

The fiber laser cutting machine has become a favorable helper for metal manufacturing projects due to its many advantages such as high precision and high efficiency, so it is also called a laser metal cutting machine. If you disassemble a fiber laser cutting machine, what are the key core components?

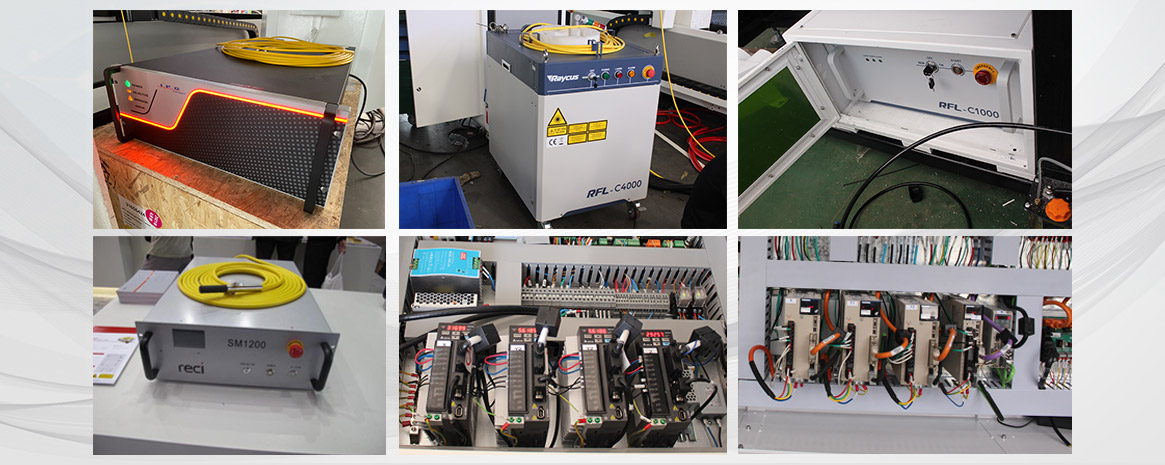

1. Fiber laser source

The fiber laser source is the most important part of the fiber laser cutting machine, which can become the "heart" of the cutting machine and the core power source of the laser machine. ACCTEK fiber laser cutting machine adopts Raycus/Reci/IPG laser source with international advanced laser technology. This series of lasers apply to many application scenarios, with a narrow seam of the cut sheet and bright section. Compared with other lasers, fiber lasers have the advantages of higher cutting efficiency, more reliable quality assurance, longer service life, and lower maintenance costs.

The laser power of the metal laser cutting machine can be selected from 1000W, 1500W, 2000W, 3000W, 4000W. The high-power fiber laser machine is especially suitable for high-speed and high-precision metal cutting. The cutting slot is very slim, which can reach up to 0.05mm.

2. Servo motor

The quality of the motor is related to the cutting accuracy of the fiber laser cutting machine. In order to make the machine cheaper, some companies usually choose a stepper motor. But the stepper motor used in the metal cutting machine often has vibration phenomenon, as the speed increases, the power will gradually decrease. ACCTEK fiber laser cutting machine adopts Taiwan Delta and Japanese Yaskawa servo motor, which have faster speed and signal feedback, which can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine.

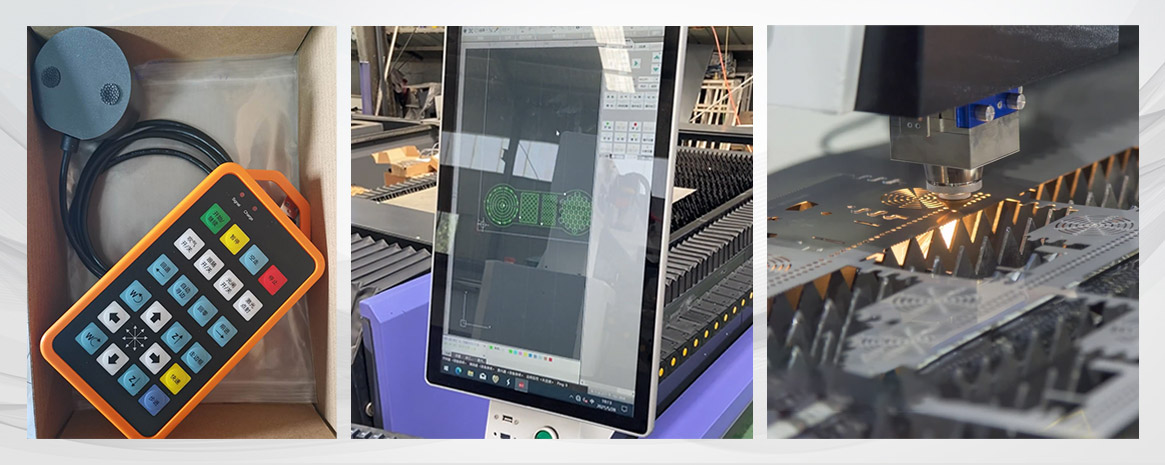

3. Control System

The control system is the dominant operating system of the fiber laser cutting machine, and its quality determines the operational stability of the fiber laser cutting machine. It mainly controls the machine tool, realizes the movement of X, Y, Z axis, and also controls the output power of the laser. ACCTEK fiber laser cutting machine adopts advanced Au3tech and Cypcut control system, which has good performance and has obvious advantages in stability, reliability, ease of use and other aspects.

4. Laser cutting head

The fiber laser cutting head is a laser output device, which consists of a nozzle, a focus lens and a focus tracking system. The cutting head of the laser cutting machine will travel according to the set cutting track. ACCTEK chooses the Raytool and Au3tech cutting head, the beam quality is excellent and stable, and it can perforate and cut various metal materials at high speed. High-grade dust-proof design, effectively avoid dust intrusion.

Fiber laser cutting adopts non-contact processing, and it has almost no consumables. And laser cutting has greater flexibility, which can reduce the investment in mold production and shorten the sample cycle of the workpiece. I believe that with the advancement of technology, the use of metal laser machines will become more and more common. In the process of choosing a laser cutting machine, you must choose the right metal cutting equipment according to your actual production needs.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd