What does the cnc router machine origin position have to do with?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

During the working process of the cnc router machine, the origin will be out of position.

During the working process of the cnc router machine, the origin will be out of position. What should I do if it encounters it? The five-axis engraving machine adopts Taiwan's Syntec control system, which has high performance and competitive price. The reason for the position shift of the origin has a certain relationship with the control system.

What is the origin of the cnc router machine?

Workpiece origin refers to the origin of workpiece coordinates, which is the origin determined for workpiece size programming. The workpiece origin can be selected by the programmer, and is generally the starting point for workpiece processing.

The engraving machine is a mechanical unit controlled by the Syntec control system. The system itself only knows that the current position is relative to the previous position. A reference point needs to be selected so that any position on the machine tool has a fixed coordinate as a parameter. This reference point is Mechanical origin.

What should I do if the origin of the engraving machine moves?

First check whether the limit can be used, generally mechanical and metal induction. If it can't be used, find the manufacturer to repair and replace it. See if the limit is loose, the limit is not triggered yet when the screw or rack ends.

If it is the mechanical origin, it will directly limit the alarm. If it is beyond the scope of the engraving machine, you need to set the soft limit in the engraving software of the cnc router machine. When the customer uses the engraving machine, he should try his best to design a reasonable cnc router machine range and set the corresponding software parameters: also check whether the limit switch is flexible and so on from time to time.

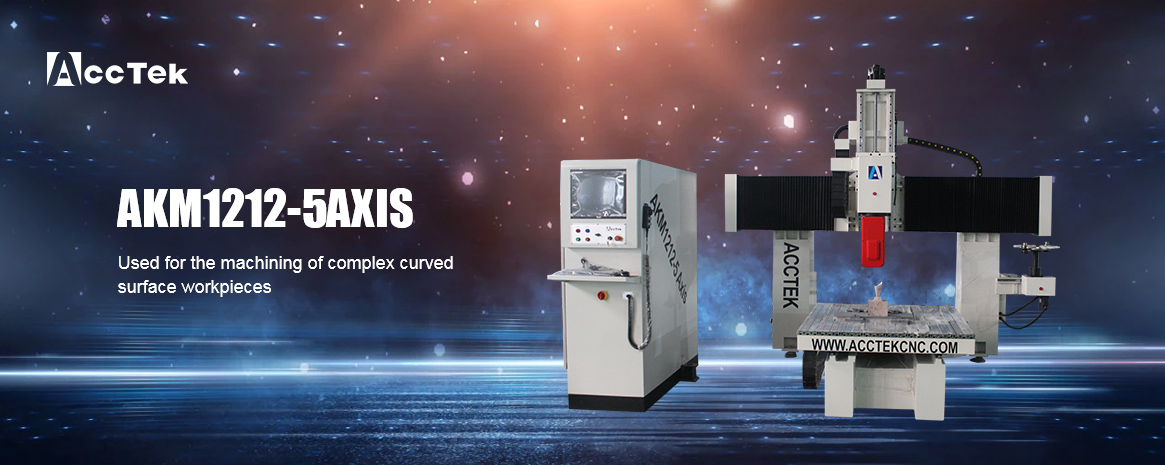

Introduction of five-axis CNC router machine

The CNC router machine AKM1325-5AXIS is specially designed for processing various large non-metallic molds. It can be used for 5D engraving and cutting foam, epoxy tooling board (processable resin board). The Z-axis stroke can be increased to 1 meter, which is very suitable for processing large three-dimensional curved surfaces. Five-axis linkage, with RTCP function (true five-axis interpolation), suitable for large-scale 3D surface processing modeling. Diversified control can separately control the processing speed, empty material speed, etc.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd