What is the difference between oscillating knife and laser cutting machine?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

The choice of oscillating Knife and laser machine should be based on the products you need to produce, each has its own advantages

Oscillating knife cutting effect

The oscillating knife will vibrate up and down when cutting, tens of thousands of vibrations per minute, similar to the principle of a saw blade, but there is no saw tooth, no powder, the vibrating knife can freely replace the cutter head, according to different materials, you can choose a round knife, Half cutter, drag cutter, bevel cutter, milling cutter, etc.

The finished products cut by oscillating knife are also clean and neat, the edges are smooth, and the size of the pieces are accurate, odorless, relatively environmentally friendly, soft and hard materials take all, and the foot cushion leather modification system is very good. Its cutting speed is twice that of a rotary knife and twice that of a laser. It is also the first choice of many companies.

Affect the cutting effect of oscillating knife

Accuracy of the table

When the accuracy of the workbench is high, the blades on the workbench will perform high-precision cutting. Of course, the accuracy is also greatly guaranteed. The height of the workbench is high or low, and subtle errors may cause the reduction of cutting accuracy, which will bring to the factory. loss. This has a particularly great impact on the quality of our materials. Where we need to consider, we must look at the whole process of cutting demonstrations to determine whether the accuracy effect is enough!

Blade sharpness

The sharpness of the cutting machine blade is also an important factor that affects the cutting accuracy. When the blade is passivated, there is a large amount of wear, which affects the cutting of raw materials during the cutting process and affects the cutting accuracy. The material of the blade is good, and the sharpness is very good, but the cutter can switch the blade, and choose different blades according to different materials. Regardless of the blade life, cutting accuracy, cutting speed and cutting quality, a good blade is much higher than a poor quality blade.

Differences in cutting materials

Depending on the cutting material, it will also affect the choice of cutting blade. Similarly, the precision of cutting cloth and white cardboard is different, mainly affected by the thickness and hardness of the material. The thicker the material, the lower the precision and the larger the gap. The multiple blades of one machine can use different blades according to the material, which cannot be reached by the laser cutting machine.

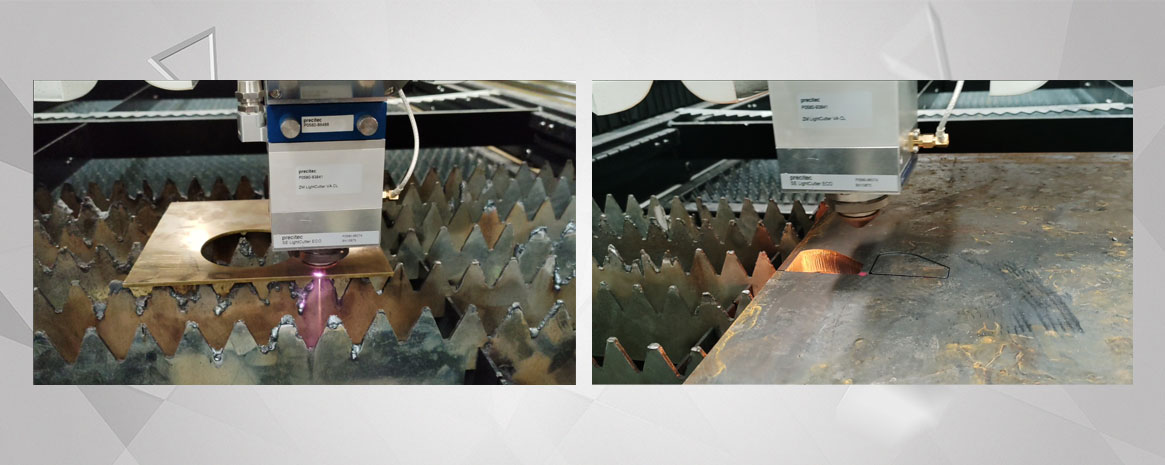

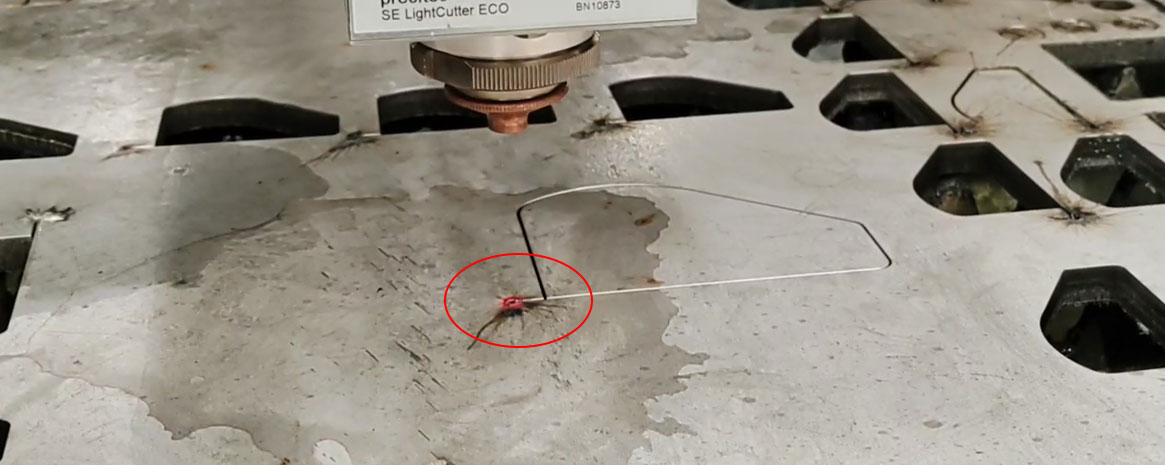

Laser cutting machine cutting effect

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting process equipment.

The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not need subsequent processing; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow; The incision has no mechanical stress, no shearing burr; high processing accuracy, good repeatability, and no damage to the surface of the material; CNC programming, can process any plan, can cut the entire board with a large format, does not need to open a mold, and is economical and time-saving .

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd