Why woodworking cnc router use of vacuum table tops?

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

The table top of the woodworking engraving machine is an indispensable part of the machined parts. If the table top is uneven, the products produced will be affected.

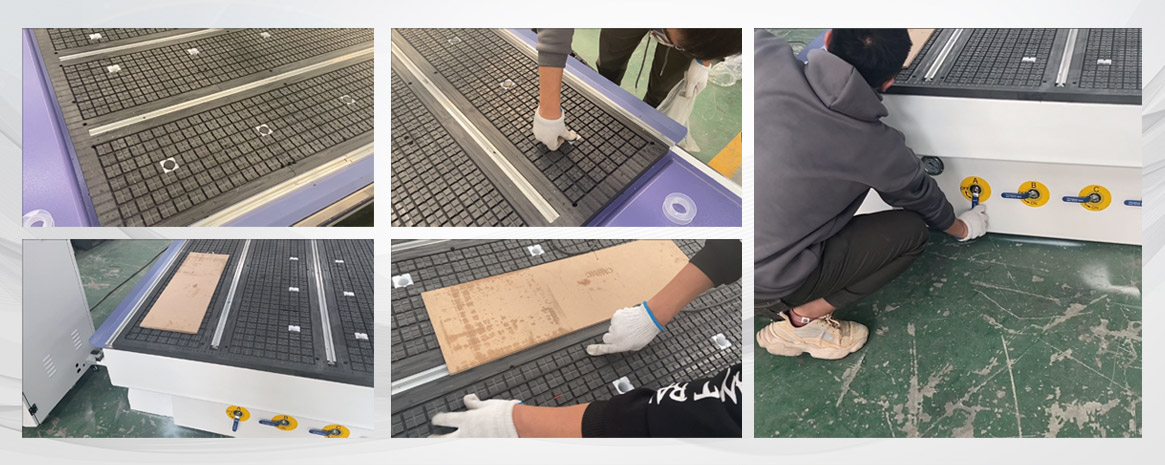

The table top of the woodworking cnc router is an indispensable part of the processed parts. If the table top has unevenness, the products produced will be affected as a result. Therefore, on the table top of the woodworking cnc router, manufacturers generally choose a vacuum table. How does the vacuum table work?

The vacuum suction table of the woodworking cnc router is to put a density board directly on the table after the sealing tape is plugged, and the vacuum pump can be turned on to suck the workpiece. This table saves fixed time and is especially suitable for mass processing in the wood door industry.

Sometimes it is necessary to put a thin ausson board first, which is formed by wood fiber and glue under high pressure. There are ducts or gaps between the wood fiber itself and the wood fiber. Therefore, the ausson board still has a certain degree breathable.

Putting the Australian pine board on the vacuum suction table of the woodworking cnc router is to prevent the milling cutter from hurting the work table. The pressure on the part close to the density board is much lower than the atmospheric pressure on the other side, forming the so-called negative pressure. Just like two pieces of glass together, it is not easy to separate the same principle. Once the seal is not tight, no negative pressure can be generated, that is, the pressure on both sides of the workpiece plate is the same, and it is easy to move.

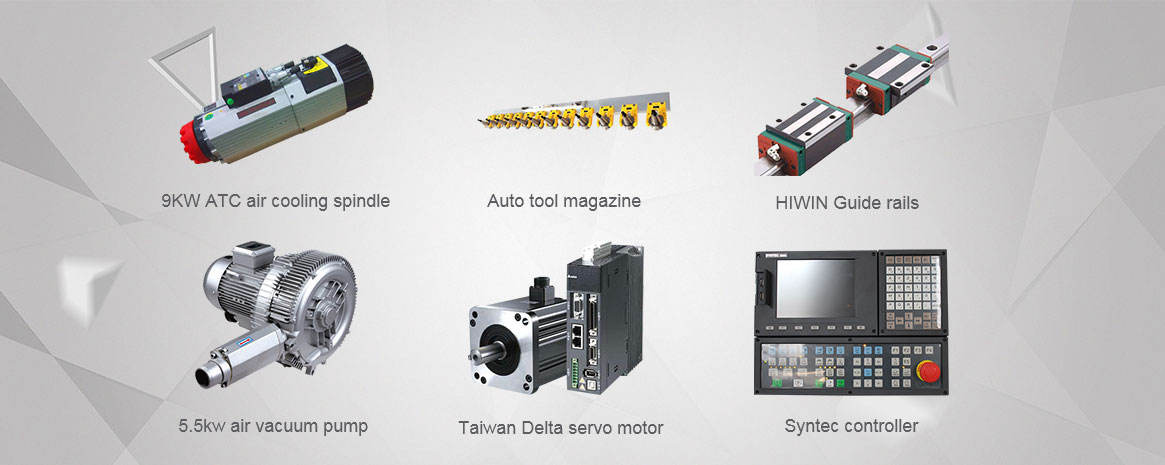

AKM1530C uses a vacuum adsorption table, other configurations are as follows, let's take a look

9.0KW ATC spindle + A cutting saw

9.0kw ATC spindle for engraving and cutting normal materials.

A cutting saw with 300mm diameter can cut maximum 50mm thickness sheet at high speed.

Auto tool magazine

8pcs linear type auto tool changers, ISO30.

Don’t need to change tools manually when machine works, which saves a lot of time and greatly improves the efficiency of material processing.

It is very suitable for complex and large-scale engraving processing.

Syntec controller

The system stability is very good, powerful functions, the operating software is simple and easy to learn, the man-machine operation is friendly.

Professionally applied to high-end cnc router machines, the anti-interference ability and control accuracy of the control system are superior to other types.

HIWIN Guide rails

Rail works with slider, drive the machine move, with good bearing capacity.

Delta servo motor

Faster speed with signal feedback. Low heat radiation.Run smoothly at ultra-low speed. Reduce the vibration, avoid oscillation.Efficient torque enhancement.

5.5kw air vacuum pump

The air between the workpiece and the worktable surface is extracted to form a negative pressure, so as to achieve the purpose of fixing on the worktable.

Double stage air pump with filter and pressure relief valve.It has less noise when working.

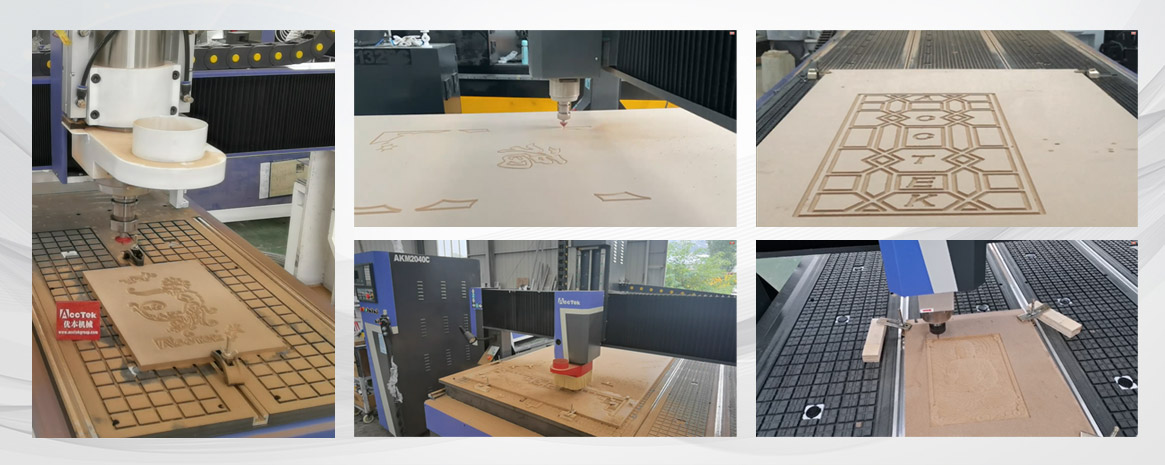

The vacuum adsorption technology is applied to the woodworking cnc router to greatly improve the work efficiency.The vacuum absorption table of woodworking engraving machine is not suitable for embossing, because the processing time of embossing is generally relatively long. If you turn on the vacuum pump to suck and engrave, it will waste electricity. Generally it is made into a 6-zone or 8-zone table, and each control valve controls a small zone. The advantage of this design is that if the fixed workpiece is relatively small, it is not necessary to open all the control valves, which also saves electricity. Point of view. The vacuum suction table is also called the suction and clamp dual-purpose double table.

If you encounter any machine-related knowledge in the process of buying a woodworking engraving machine, you can consult our staff, and we will have professional technicians online to answer your questions

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd