What should be paid attention to when using ATC CNC Router

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

The automatic tool changer spindle is the core component of the ATC CNC router. Correct use can effectively ensure the accuracy and service life of the spindle.

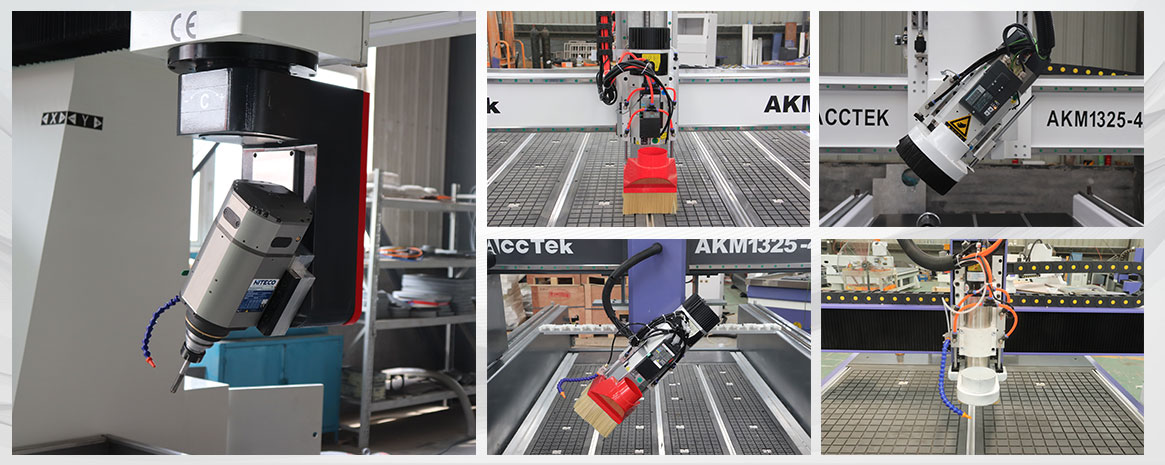

For the automatic tool changer cnc router machine, the ATC spindle is the core component of the machine. The efficiency of the spindle affects the processing. The high-power spindle cuts faster and the workpieces processed are better. ACCTEK atc cnc router machine chooses 9.0KW Chinese famous brand HQD or Italian HSD air-cooled spindle. No water pump is needed, so it is very convenient to use.

The advantages of ATC spindle motor of carving machine are high speed and good precision. Therefore, we should pay attention to some details in use to avoid damage.

1. CNC router ATC spindle and frequency inverter should be used together. The specifications and parameters of the inverter should match the rated parameters of the spindle. If not set correctly, the engraving motorized spindle will be burned.

2. Air-cooled ATC spindle:we should check it first when using it. If there is any blockage in the air duct, it should be blown through with compressed air in case of emergency.

3. Water-cooled ATC spindle: before use, it is necessary to ensure the normal operation of the cooling circulation system. It is strictly prohibited to use it without cooling conditions. The cooling water quantity is calculated according to 1 liter/kilowatt minute. The minimum flow rate of cooling water is not less than 5 liters/minute. The connection between cooling water pipe and nozzle must be reliable and non-leakage.

4. The coolant must be clean and the temperature should be controlled at 5-30 C. Cooling medium must be forced refrigeration.

5. Before using the cnc router machine, the ATC spindle should be started at the lowest speed. After 30 minutes, the differential progression of the motorized spindle should be 3000. If starting the ATC spindle directly at high speed, abnormal noise, heating and other phenomena will occur, which will affect the service life of the main bearing. It’s necessary to power on the ATC spindle (at low speed) for at least 15-30 minutes in a week during long-term preservation.

6. When fixing cutters on carving machine motorized spindle, it is necessary to clean the conical holes in the cylinder clamp and nut so as to avoid affecting the accuracy.

7. Check the rotation direction of the CNC router ATC spindle which should be the same as that of the milling cutter. If it does not conform to the three power lines, we should change two arbitrarily to make it consistent with the direction of the milling cutter.

Advantages of ACCTEK automatic tool change cnc router machine:

In addition to the high-power ATC spindle, the ACCTEK atc carving machine also uses a stable servo motor (Delta/Yaskawa) to make the machine run smoothly at high speed.

Because the servo motor runs faster, our cnc router body adopts a heavy-duty body to ensure that the machine runs at high speeds more stable and the carving material accuracy is higher.

Each of our ATC carving machines adopts Vacuum &T slot table dual-purpose table. The table can adsorb different size materials and strong suction of 250m³/hour. The adsorption countertop is partitioned, and the non-integral plate can open just one adsorption zone. Attain the goal of saving electricity.

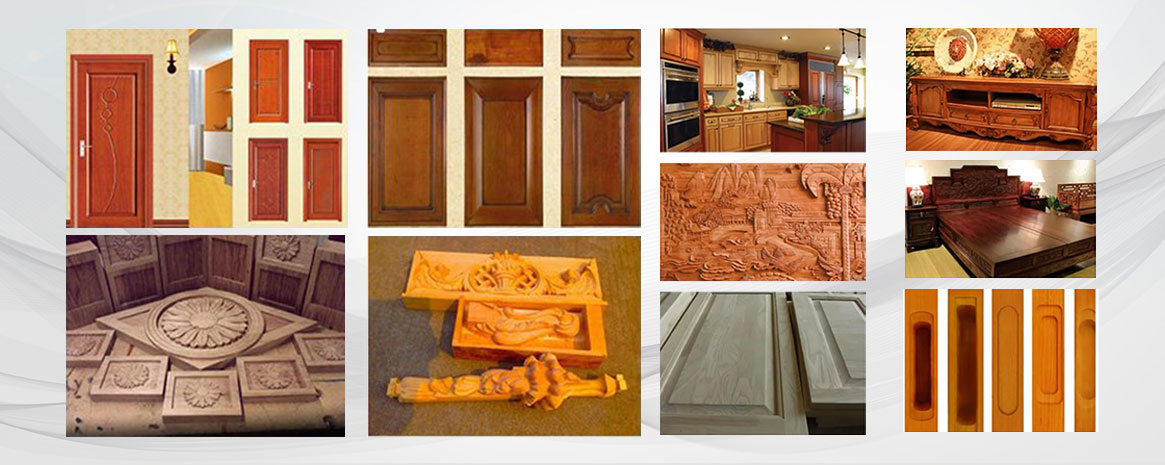

The ATC CNC router machine is used in various woodworking carving industries, which greatly improves the efficiency of engraving and cutting, and can save you labor costs. If your shop plans to expand, you can learn about our carving equipment online, and believe it can help you expand your market.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd