Why can't it cut through during laser cutting and how to solve it

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

In the process of laser cutting, the problem of not cutting through often occurs. So how can we solve this problem?

Metal laser cutting machine as a sharp tool of mechanical metal processing and manufacturing industry, many related enterprises will use it to replace the traditional cutting equipment.

However, this large precision equipment will have many problems due to improper operation or lack of maintenance. In the process of cutting, the problem of not cutting through often occurs.

So how can we solve this problem?

If the cutting speed is too fast, the focusing lens is damaged, the focusing effect is poor, the light path is not correct, and the voltage is unstable, all these are the reasons why the laser cutting is not all the way through.

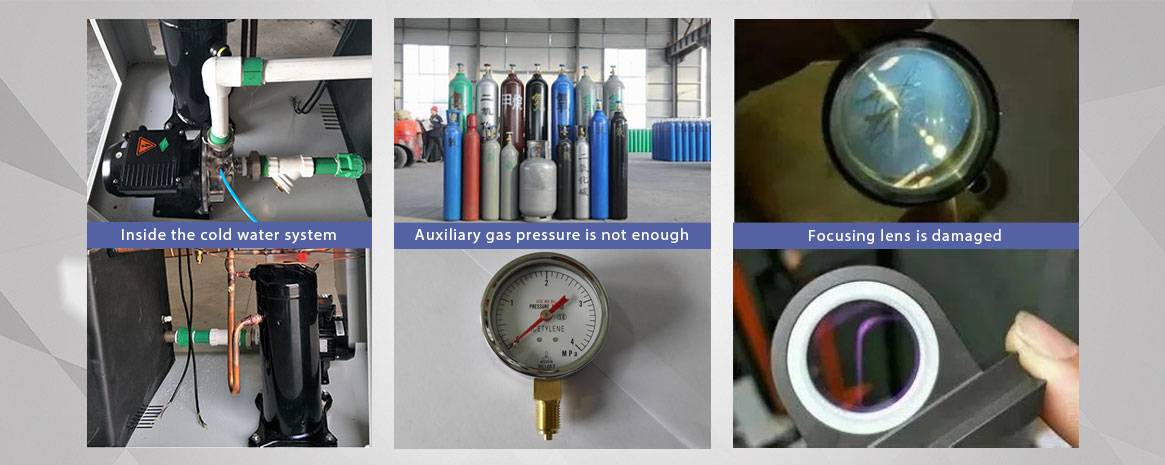

Of course, there are many factors that cause the incision is not smooth or cut through, such as the material itself, the auxiliary gas pressure is not enough, the cooling system water turbidity, poor heat dissipation effect and so on.

We should take the problem of laser cutting not through seriously and find out the solution to these problems, which is of great significance to improve the production efficiency and ensure the quality of laser cutting.

It is necessary to reduce the cutting speed properly, clean the contaminated mirrors timely and reasonably, and replace the focusing lenses.

If the light path is not correct, you can readjust the light path and adjust the focal length until the laser makes a round spot on the paper.

When cutting copper and aluminum, it is better to polish the surface or apply light absorbing material in advance to deal with the problem of high reflection rate.

Clean the foreign matters in the nozzle regularly, increase the pressure of the auxiliary gas, and change the distilled water of the cooling system in time.

These measures can effectively solve the problem that the sample is not cut through, and hope to help you

Any mechanical equipment will encounter some problems during long-term use. ACCTEK has professional after-sales technicians who can give you the necessary help when operating the machine. Including the basic training before using the machine and the technical problems encountered during the operation, let these all be handed over to the technical team of ACCTEK.

The ACCTEK's product videos can be seen on Facebook and YouTube. Search for AccTek CNC on Facebook and AccTek China on Youtube. You can learn more about CNC knowledge.

However, this large precision equipment will have many problems due to improper operation or lack of maintenance. In the process of cutting, the problem of not cutting through often occurs.

So how can we solve this problem?

Why can't it cut through during aser cuttingl?

There are many reasons for the failure of the cutting. The most common one is that the power of the laser is reduced or the lamp tube is aging, which makes the energy of the laser beam insufficient, resulting in the failure of the sample cutting through.If the cutting speed is too fast, the focusing lens is damaged, the focusing effect is poor, the light path is not correct, and the voltage is unstable, all these are the reasons why the laser cutting is not all the way through.

Of course, there are many factors that cause the incision is not smooth or cut through, such as the material itself, the auxiliary gas pressure is not enough, the cooling system water turbidity, poor heat dissipation effect and so on.

We should take the problem of laser cutting not through seriously and find out the solution to these problems, which is of great significance to improve the production efficiency and ensure the quality of laser cutting.

How to solve the problem of laser not cutting through?

For the problem that the laser power drops and the current is small, we should replace the laser tube in time and use a larger voltage regulator to increase the laser current output and improve the output power.It is necessary to reduce the cutting speed properly, clean the contaminated mirrors timely and reasonably, and replace the focusing lenses.

If the light path is not correct, you can readjust the light path and adjust the focal length until the laser makes a round spot on the paper.

When cutting copper and aluminum, it is better to polish the surface or apply light absorbing material in advance to deal with the problem of high reflection rate.

Clean the foreign matters in the nozzle regularly, increase the pressure of the auxiliary gas, and change the distilled water of the cooling system in time.

These measures can effectively solve the problem that the sample is not cut through, and hope to help you

Any mechanical equipment will encounter some problems during long-term use. ACCTEK has professional after-sales technicians who can give you the necessary help when operating the machine. Including the basic training before using the machine and the technical problems encountered during the operation, let these all be handed over to the technical team of ACCTEK.

The ACCTEK's product videos can be seen on Facebook and YouTube. Search for AccTek CNC on Facebook and AccTek China on Youtube. You can learn more about CNC knowledge.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd