Application and advantages of ball screw in CNC

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

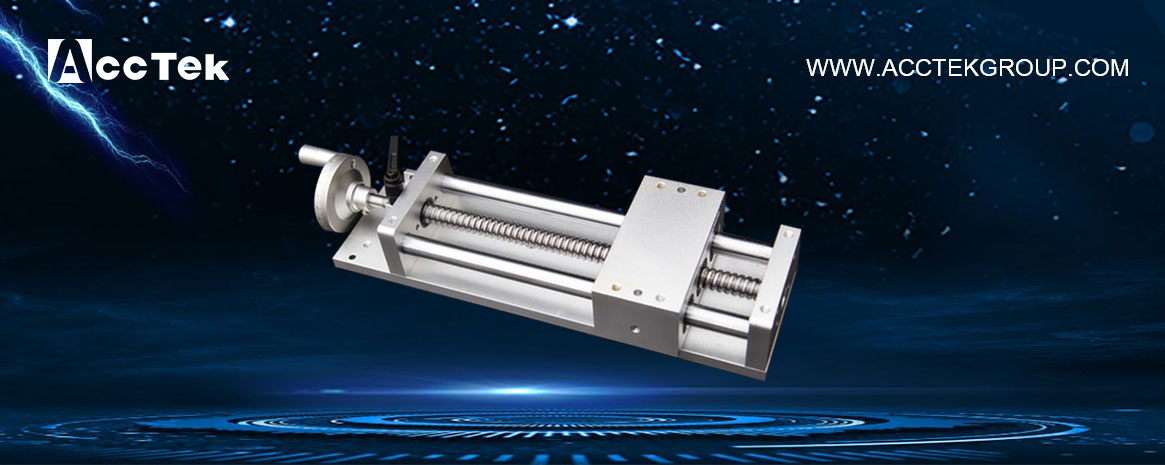

In the cnc router and laser cutting machine, the ball screw is an indispensable machine part, so what are its advantages?

In the transmission industry, the ball screw is an indispensable mechanical component. It is the most commonly used transmission unit in tool machinery and precision machinery, Its main function is to convert rotary motion into linear motion.

Due to its low friction resistance, ball screws are widely used in various industrial equipment and precision instruments. In cnc router machines and laser cutting machines, ball screws are also indispensable machine parts.

When the screw or nut rotates, the balls are deflected by the deflector to the ball return system of the nut, and they travel through the return system in a continuous path to the opposite end of the ball nut. The ball then exits from the return system to the ball screw and nut threaded raceway for recirculation in a closed loop.

The ball nut determines the load and life of the ball screw assembly. The ratio of the number of threads in the ball nut circuit to the number of threads on the ball screw determines that the ball nut will reach fatigue failure (wear) faster than the ball screw.

In a large-size cnc machines, because there is a larger processing area, the X-axis and Y-axis have a longer running stroke. At this time, the X-axis and Y-axis are driven by rack and pinion, and the Z-axis is driven by screw.

Load Capabilities – A part of what makes ball screws versatile in so many industries is their ability to carry remarkably heavy loads at fast, efficient speeds.

No side clearance, high rigidity - Ball screw can be preloaded, because the preloading can make the axial clearance reach negative value, and then get higher rigidity.

Although the ball screw drive has many advantages, different machines have great differences in application fields and performance, so different mechanical equipment needs to choose the appropriate transmission mode according to their own characteristics. Only with the most suitable configuration can the machine maximize its value and bring the highest benefits to the shop.

The ACCTEK's product videos can be seen on Facebook and YouTube. Search for AccTek CNC on Facebook and AccTek China on Youtube. You can learn more about CNC knowledge.

Due to its low friction resistance, ball screws are widely used in various industrial equipment and precision instruments. In cnc router machines and laser cutting machines, ball screws are also indispensable machine parts.

How does a ball screw work?

The ball screw assembly is composed of screw and nut, each has a matching spiral groove. The balls roll between these grooves, providing the only contact between the nut and the screw.When the screw or nut rotates, the balls are deflected by the deflector to the ball return system of the nut, and they travel through the return system in a continuous path to the opposite end of the ball nut. The ball then exits from the return system to the ball screw and nut threaded raceway for recirculation in a closed loop.

The ball nut determines the load and life of the ball screw assembly. The ratio of the number of threads in the ball nut circuit to the number of threads on the ball screw determines that the ball nut will reach fatigue failure (wear) faster than the ball screw.

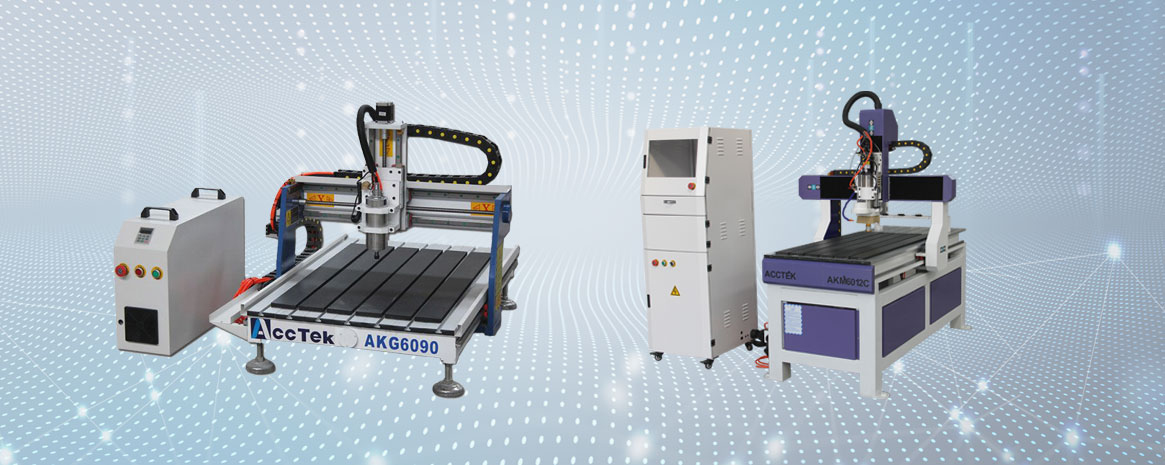

Application of Ball Screw in CNC Router Machine

Ball screws are usually used for the three axes of a small cnc router or the Z axis of a large size cnc router. In the small cnc machines, because the X-axis and Y-axis have a short movement stroke, ball screws are usually used for the three axes. Under the condition of ensuring the running speed, the machine can run more accurately.In a large-size cnc machines, because there is a larger processing area, the X-axis and Y-axis have a longer running stroke. At this time, the X-axis and Y-axis are driven by rack and pinion, and the Z-axis is driven by screw.

What are the advantages of ball screw in CNC?

High Efficiency – Ball screws typically operate at a minimum of 90 percent efficiency, which makes them an optimal choice in converting rotary motion into precision linear motion.Load Capabilities – A part of what makes ball screws versatile in so many industries is their ability to carry remarkably heavy loads at fast, efficient speeds.

No side clearance, high rigidity - Ball screw can be preloaded, because the preloading can make the axial clearance reach negative value, and then get higher rigidity.

Although the ball screw drive has many advantages, different machines have great differences in application fields and performance, so different mechanical equipment needs to choose the appropriate transmission mode according to their own characteristics. Only with the most suitable configuration can the machine maximize its value and bring the highest benefits to the shop.

The ACCTEK's product videos can be seen on Facebook and YouTube. Search for AccTek CNC on Facebook and AccTek China on Youtube. You can learn more about CNC knowledge.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd