What is a 5-Axis Machine and Why choose it

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

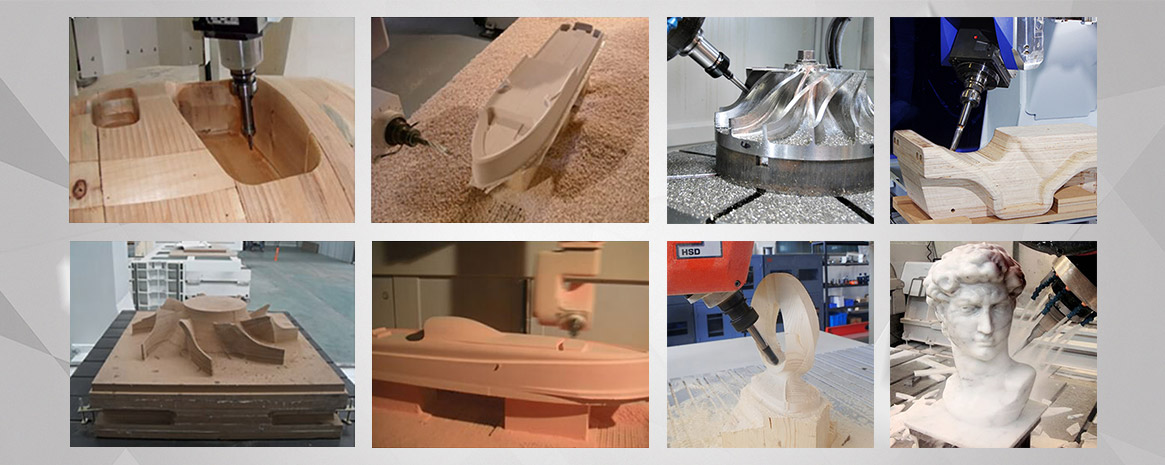

As technology changes, the application of 5-axis machining is on the rise. What is a five-axis cnc machine and what are its advantages?

CNC machining is a procedure used in most manufacturing operations and is widely used in most industries. CNC, which stands for Computer Numeric Control and deals with the use of a single-setup or more computer to administer actions of different machine tools like lathe, router, and mill.

With the development of science and technology, five-axis cnc router machines are increasingly used in various engraving industries. It is favored by many users with its unique processing advantages.

What Is 5-Axis Machining

5-axis machining refers to a machines ability to move a tool or a part in five different axes simultaneously. 5-axis machining offers three linear axes and two rotational axes that work simultaneously to achieve complex surface machining. This gives room for the production of very intricate parts, and that is why 5-Axis CNC milling is very common in aerospace operations.

Pros Of 5-Axis Machining

5-axis machining is a high-tech method that makes impossible into possible, and all spatial surfaces or unusual shape machining or production can be done. It can not only complete the processing tasks of complex parts and industry products but also can quickly improve the processing efficiency and shorten the processing flow.

5-axis machining has featured in high efficiency and high precision, and the workpiece can be finished by only clamping in one time. It is suitable for the processing of modern molds such as auto parts and aircraft structural parts. 5-axis machining is not only used in civil industry but also widely used in aerospace, military, scientific research, precision instruments, high-precision medical device industry.

Through the 5-axis machining technology, the problem of re-positioning the workpiece at a complex angle in accuracy many times has been solved. It not only shortened the time but also greatly improved machining tolerance in many times. The high cost of making multiple jigs in the traditional way has also been saved. 5-axis machining can process complex parts, such as drilling, taper machining, cavity crypts for complex surfaces, etc., which are not possible with traditional machining methods in most times.

Another inherent advantage of five-axis machining is it can use shorter tools because the tool/toolholder combination can be tipped away from otherwise interfering surfaces or features on the workpiece. This is particularly important in die and mold work where the use of toolholder extensions is common to reach deep cavity surfaces. A shorter tool results in less vibration, allowing for heavier or faster cutting, better surface finish and longer tool life.

As technology changes, the application of 5-axis machining is on the rise. Ultimately, your workload and productions targets determine the machining equipment you choose. Whether you think five-axis machining isn’t for your shop or you’re satisfied with ten-year-old technology, it’s time to take another look. To help you understand which type of machine tool might be best for your shop, you can communicate with our staff online. We will provide you with effective suggestions and suitable solutions.

With the development of science and technology, five-axis cnc router machines are increasingly used in various engraving industries. It is favored by many users with its unique processing advantages.

What Is 5-Axis Machining

5-axis machining refers to a machines ability to move a tool or a part in five different axes simultaneously. 5-axis machining offers three linear axes and two rotational axes that work simultaneously to achieve complex surface machining. This gives room for the production of very intricate parts, and that is why 5-Axis CNC milling is very common in aerospace operations.

Pros Of 5-Axis Machining

5-axis machining is a high-tech method that makes impossible into possible, and all spatial surfaces or unusual shape machining or production can be done. It can not only complete the processing tasks of complex parts and industry products but also can quickly improve the processing efficiency and shorten the processing flow.

5-axis machining has featured in high efficiency and high precision, and the workpiece can be finished by only clamping in one time. It is suitable for the processing of modern molds such as auto parts and aircraft structural parts. 5-axis machining is not only used in civil industry but also widely used in aerospace, military, scientific research, precision instruments, high-precision medical device industry.

Through the 5-axis machining technology, the problem of re-positioning the workpiece at a complex angle in accuracy many times has been solved. It not only shortened the time but also greatly improved machining tolerance in many times. The high cost of making multiple jigs in the traditional way has also been saved. 5-axis machining can process complex parts, such as drilling, taper machining, cavity crypts for complex surfaces, etc., which are not possible with traditional machining methods in most times.

Another inherent advantage of five-axis machining is it can use shorter tools because the tool/toolholder combination can be tipped away from otherwise interfering surfaces or features on the workpiece. This is particularly important in die and mold work where the use of toolholder extensions is common to reach deep cavity surfaces. A shorter tool results in less vibration, allowing for heavier or faster cutting, better surface finish and longer tool life.

As technology changes, the application of 5-axis machining is on the rise. Ultimately, your workload and productions targets determine the machining equipment you choose. Whether you think five-axis machining isn’t for your shop or you’re satisfied with ten-year-old technology, it’s time to take another look. To help you understand which type of machine tool might be best for your shop, you can communicate with our staff online. We will provide you with effective suggestions and suitable solutions.

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd