High quality cnc router machine for round material wood

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/shijian.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/zuozhe.png)

![[field:title /]](https://www.acctekgroup.com/templets/youben/images/cishu.png)

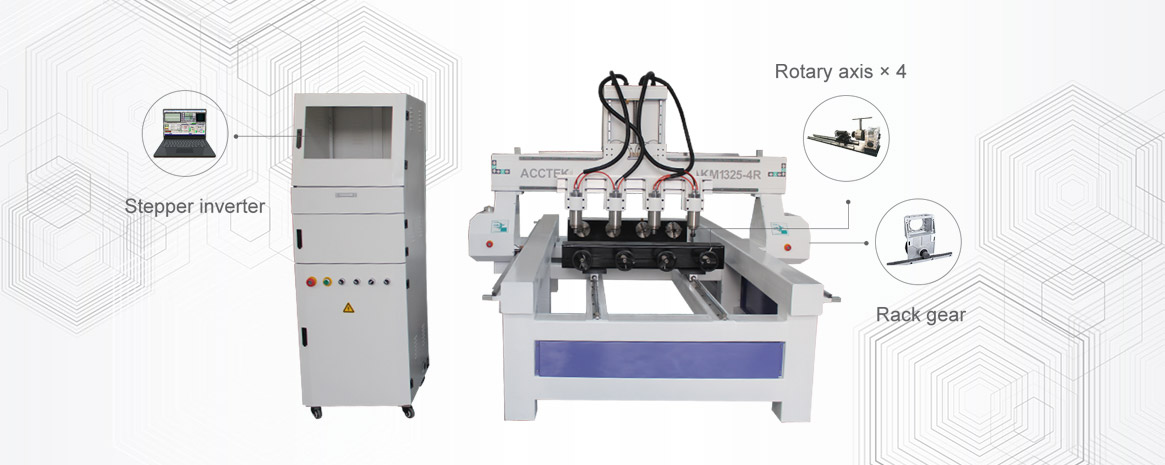

High quality cnc router machine for round material wood cnc 1325 furniture making machine with rotary axis

Features of 4 axis rotary axis cnc wood router

High quality cnc router machine for round material wood cnc 1325 furniture making machine with rotary axis

Features of 4 axis rotary axis cnc wood router

1)integrally cast lathe bed, solid and stable ,high rigidity and high accuracy.

2) Four axis machine, with 4 Rotaries and 4 spindles, which can work at the same time or independently, and every one's max effective working area is 200mm(diameter) by 2000mm(length).

3) Has the 4th rotary which is used for engraving cylinder workpiece.

4)Compatible software: Open style software interface. Our software is compatible with TYPE3/ARTCAM/CASTMATE/UG and many other kinds of CAD/CAM software, can change the working file into G code, guarantee that the design does not have the barrier.

Advantages of 4 axis rotary axis cnc wood router

1. The Z axis use precision ball screw, low friction, high efficient and precision

2. Guide rail: adopt Taiwan HIWIN square linear guide, high speed, long operating life.

3. Lathe bed is welt with all-steel and age after finishing, more stable, durable and expensive.

4. Machine casing: factory customization, electrostatic plastic absorbing and no peeling paint

5. Portal frame: use aviation industry aluminum, long service time, resistant to wear and low noise

6. Principal axis: water cooling principal axis, cooling the machine timely and effectively.

7. Has the function of re-carving after break point and power failure. Has the function of forecasting process time.

8. Perfect oil-inject system makes maintenance much easier.

9. Has duct-collect function. It will clean up the carving residuum and make the operations tidier and more convenient.

10. Advanced design of the machine make sure strong cutting and guarantee the engraving precision.

Main configurations of 4 axis rotary axis cnc wood router

#4pcs 2.2kw water cooling spindle

#4pcs 125*2000mm rotary(can work on 200mm diameter round materials maximum)

#XY axis gear transmission, Z axis Taiwan TBI ball screw transmission

#Taiwan Hiwin 20mm rails

#Mach3 controller with USB port

#450B stepper motor(NEMA34) on ZY axis, 450C stepper motor for rotary

#Yako 2D811 driver

#Fuling inverter

#Leadshine M860 driver

#Filter, oil lubrication, tool sensor

Application of AKM1325-4R furniture making machine

This mahcine is mainly used for processing Roman column, stair handrails, chair legs, etc. symmetric cylindrical products. Can be processed cylinder, cone, surface, a complicated shape such as spherical rotary body semi-finished wood products or wood. Especially suitable for mass production of small and medium wood enterprises, they can always be set flexibly shape, rapidly changing processing styles.

Wood processing: processing of various furniture such as door, window, cabinet, craft, wood door, wood screen and so on.

Advertisement: engraving and cutting MDF,acrylic,PVC,various labels and nameplate.

Art craft: engraving characters of any languages and graphics on gifts and souvenirs.

Wood, aluminium board, plastic, density board, wave board, PVC, acrylic, crystal, light marble etc.

Package

(1). The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the testing video.then you pay 70% balance payment,we arrange shipping for you.

(2). Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool

(3). Fumigation wooden box

(4). Whole film packaging machine

(5). The package is tandard exporrt plywood box,customized for every size machine.

Payment :

1. We accept Western union, Moneygram, TT, Trade assurance of Alibaba, and you can pay 30% in advance, 70% before delivery.

2. The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the testing video.

3. After you agree, please finish the balance.Finally.we arrange the delivery.

4. Its need about 10 days to produce the machine after get your deposit.

5. All thing is tested well,then we arrange the delivery.

After sale service of AccTek:

1. 18 months guarantee of the whole machine.

2. Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

3. Lifetime maintenance free of charge.

4. We will provide the consumable parts at a factory price when you need replacement.

5. Machine has been adjusted before delivery.

6. Our technician can be sent to your company to install or calibrate if necessary.

Jinan AccTek Machinery Co.,Ltd specializes in manufacturing CNC Router and Laser machines.

Since 2005 we have been based in the Industrial Zone of Jinan City, Shandong Province south of Beijing.

Our main products are AccTek CNC Routers and Laser engraving and cutting machines. Stock or custom configurations are our specialty. Components for our machines are sourced from world class suppliers and innovators in machine control.

These machines are used in many industries, crafts and arts businesses around the world. These include woodwork, metal and stone work, aluminum fabrication, boat building, shop fitting, mold making, to name a few.

Our dedicated and highly skilled after sales service department, sales team, and thorough quality assurance procedures mean that you can buy with confidence.

Now we own two workshops,one for cnc router and another for laser machines. Which covers 3000,0square meters. There are 40 members in manufacturing and 21 members for marketing and service.

If you are interested in our cnc router, welcome to our official website for more information.

woodworking cnc router | 3d cnc machine | china cnc router

woodworking cnc router | 3d cnc machine | china cnc router

Product Directory

Copyright © Jinan AccTek Machinery Co.,Ltd