Analysis of the core parts and technical parameters of laser cutting machine

Laser cutting machine is a highly integrated equipment integrating machine and electricity, with high technical content, good machining accuracy and high flexible production efficiency, which is conducive to increasing the utilization efficiency of materials, reducing the production and processing cost of products and reducing the labor intensity of workers.The precision of laser cutting machine depends on the design of the key parts of the machine.

It can be known from the force analysis of the working table that the laser cutting machine does not contact directly with the processed parts, but the workpiece is processed by laser beam within a certain range, so in the process of processing parts, the cutting force is zero.According to the previous design experience, determine the length direction of the table, width direction and height direction of the size, after the determination of the table and its accessory workpiece material and weight preliminary estimate.

Design and calculation of ball screw drive system

(1) Revolving speed of lead screw under various cutting forces

Axial load of lead screw: Fi= PXI +W/10;Vmax -- the maximum moving speed of the workbench;Nmax -- maximum motor speed;I -- Transmission ratio;Pxi -- longitudinal cutting force;W -- Workpiece weight plus workbench weight.

(2) Strength calculation formula of axial load:F -- Cutting force, F=0;U -- Coefficient of rolling friction on the rolling guide.

(3) Transmission efficiency of ball screw pair The transmission efficiency of ball screw pair is:;Bits - the ball screw thread Angle;'-- equivalent Angle of friction.

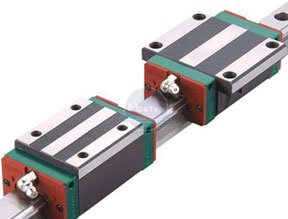

Selection and calculation of guide rail

Guide type and performance guide classification methods are many, according to the nature of contact surface can be divided into, sliding, rolling, fluid guide.The most basic requirements of the mechanical system for the guide are: good accuracy, high rigidity, smooth operation, good corrosion resistance, insensitive to temperature influence and good machinable performance. The guide material is generally cast iron or non-ferrous metal. In the case of high bearing capacity requirements, the cast iron material is generally selected for casting, and then secondary processing;Nonferrous metal direct drawing is generally adopted in the working condition where the bearing capacity is not high.The precision of the guide requires very high precision of the guide.The grade of geometric accuracy is generally between 6 and 7. If there are special requirements, the accuracy should be improved.The accuracy class of shape and position tolerance of guide rail is generally between 1 and 3;The surface of guide rail needs precision grinding, and the surface roughness is generally controlled between Ra= (0.63 ~ 2.5), especially the high-precision surface roughness below 0.63.

Model selection calculation of step motor

Key points of stepping motor selection The precision of stepping motor is generally between (0.03 ~ 0.05) of stepping Angle.Determine the power of the stepping motor to ensure that the permissible range of calorimetry of the stepping motor, so that the magnetic steel in the stepping motor is not demagnetized;According to the calculated theoretical torque to choose the appropriate stepping motor, because the greater the stepping motor torque, the greater the response electromotive force, if not controlled within a certain range, will lead to the decline of the torque;The starting frequency of the stepping motor should be determined according to the design requirements. The starting frequency of the stepping motor should not be too high, otherwise the precision of the stepping motor will be affected.To obtain a higher speed, the stepper motor should be started at a low frequency and then accelerated according to a certain rule until the desired speed is achieved.

Product Directory