In various engraving industries, for some companies with larger production scales or considering expansion, production efficiency is often more important than machine cost. Higher efficiency and less labor costs will result in more revenue and profits. If you are considering expanding your business scope, an

cnc engraving machine with automatic tool change is the best choice.

What is an Automatic Tool Changer?

An automatic tool changer often referred to as an ATC, is used to improve both the production and the tool carrying capacity of a computerised numerical control or CNC machine tool. It does this by allowing the machine to work with various different tools. As such it is part of the process to achieve full automation.

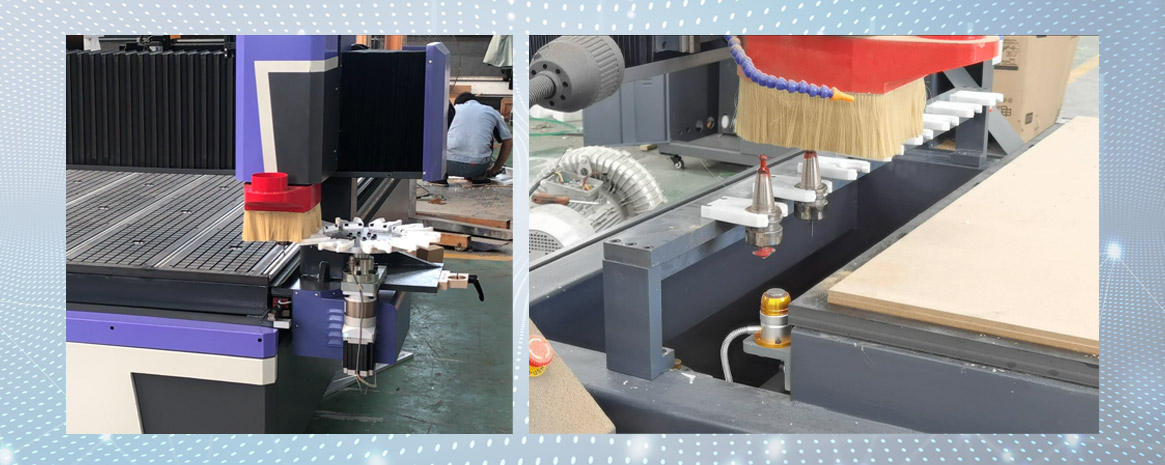

An automatic tool changer is generally comprised of a base, arms with a gripper, a tool holder and a support arm as well as the tool magazines. The array of tools are stored within a magazine which allows the machine to access a wider variety of them without the need for an operator.

An ATC is capable of increasing the speed and accuracy as well as the reliability of a CNC machine but it does have certain requirements. Some of these include the need for the tools to be easy to centre as well as simple for the grabber arm to hold as well as easy to automatically disengage. To provide this, tools used in an ATC are usually held by specially designed tool holders.

What are the types of Automatic Tool Changers?

ATC come in two variants depending on the magazine’s shape. Some are on rotary holders on a turntable type setup with claws holding each tool in its own location. Some are straight static racks of tools that are mechanically much simple.

If you need to know about an

ATC CNC Router machine, you can learn about the product performance and price on the ACCTEK official website. If you have any questions, you can communicate with our staff online, we are honored to help you.

What are the advantages of ACCTEK automatic tool changer?

ACCTEK automatic CNC tool changer has numerous significant benefits in the shop. It allows for a large number of tools to be stored locally to the machine each of which is returned automatically when its task is complete.

The

ATC CNC Router machine can switch between a large number of tools without manual operation, reducing downtime and total production time. Not only improves the efficiency of the machine, but also reduces labor costs.

How does an automatic tool changer work?

Once set up on your CNC machine, an automatic tool changer follows a quick set of steps to swap tools in and out. Here’s how it works.

First, the automatic tool changing command is given. The tool that is going to be changed moves into the tool change position. The ATC arm then moves into the position so it can pick up the tool. One gripper arm moves the new tool to the turret while a second removes the old tool.

In a matter of seconds, an ATC enables you to switch tools automatically without any need for human involvement (apart from programming the change).

At ACCTEK, our engineers have extensive expertise in motion control, and have always aims to provide engraving machine users with high-precision, high-efficiency, and high-quality CNC machine tools.

Whatever your goals may be, we are dedicated to helping you produce outstanding results at a fraction of the labor and cost.