When using a

fiber laser cutting machine to cut metal materials, there are many factors that affect the quality of laser cutting. Today we will introduce to you the reasons that affect laser cutting and how to improve the quality of metal cutting from both cutting speed and laser power.

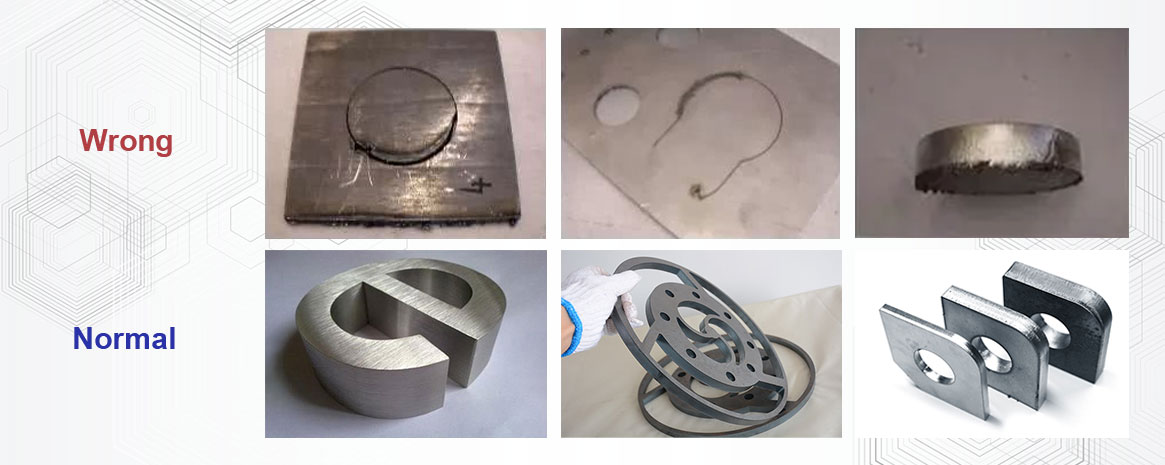

Effect of cutting speed on laser cutting quality

The effect of too fast cutting speed

(1) It may cause uncutting and reverse spray phenomenon.

(2) Some areas can be cut, but some areas cannot be cut off.

(3) The entire end face is thicker, but no melt is generated.

(4) The cut section is shown as a cross grain and the lower half is melted.

In general, the cutting speed is too fast, the gas pressure is low, and the power is low, and as a result, the cutting is insufficient.

The effect of feed rate is too slow

(1) The over-melting condition is caused, and the cut end face is rough.

(2) The slit will also be widened and melted when the sharp corner is cut.

(3) Affecting cutting efficiency.

In general, the cutting speed is too slow, the air pressure is too high, and the power is too large, and as a result, the cutting over-melting phenomenon is caused.

Appropriate feed rate selection

From the cutting spark, it can be determined whether the feed rate can be increased or decreased; when the correct cutting speed is set, the spark spreads from top to bottom.

If the spark is tilted, the feed rate is too fast, the auxiliary gas is not completely blow away the slag, and the cutting head has moved forward.

The sparks are non-diffusing and less, and when they are condensed together, the speed is too slow, and the auxiliary gas is excessively blown, so the workpiece section is easily rough.

Adjusting the appropriate feed rate, the cut surface shows a smoother line, and no melts in the lower part.

Effect of laser power (W) on laser cutting quality

The laser power (W) is too small to be cut.

The laser power (W) is set too large and the entire cut surface is melted.

The laser power (W) is insufficiently set, and the melt is generated after cutting.

The laser power (W) is set properly, the cut surface is good, and no melt is generated.

Factors affecting the laser power (W);

1) lens pollution

2) the focus position is incorrect

3) there are rust spots and oil spots on the surface of the board.

These are two important factors that affect the quality of

fiber laser cutting. There are many other reasons that also affect the quality of metal material cutting. We will continue to introduce you in the following posts, and hope it will be helpful for you to operate the fiber laser machine correctly.