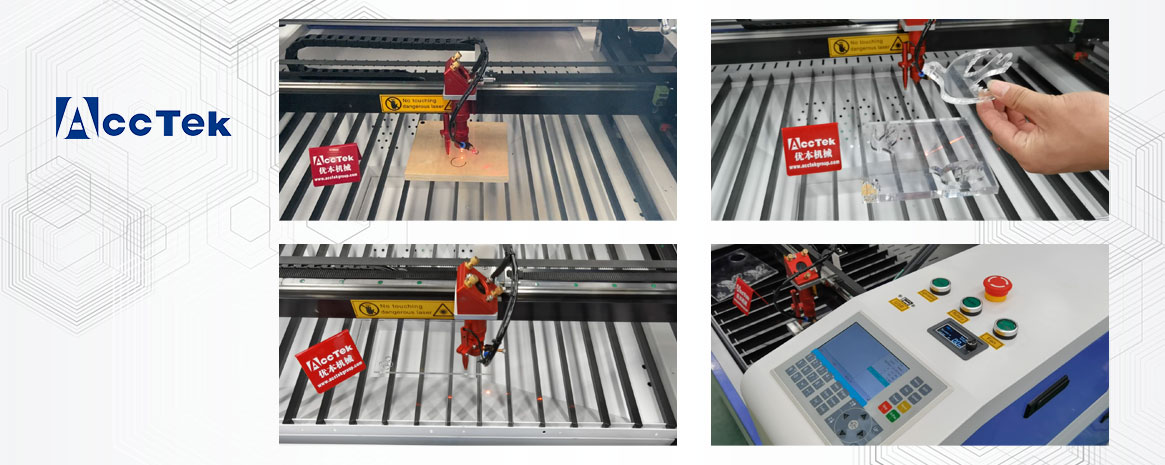

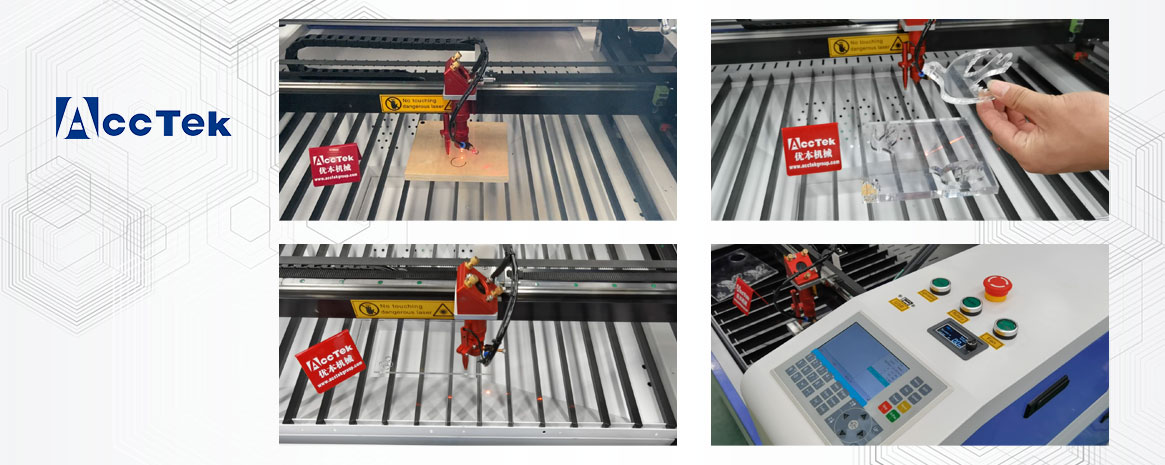

1. The cutting principle of the

co2 laser machine is to use the high-speed laser beam generated by the laser tube to heat the physical surface to generate high temperature, and then quickly decompose the physics.

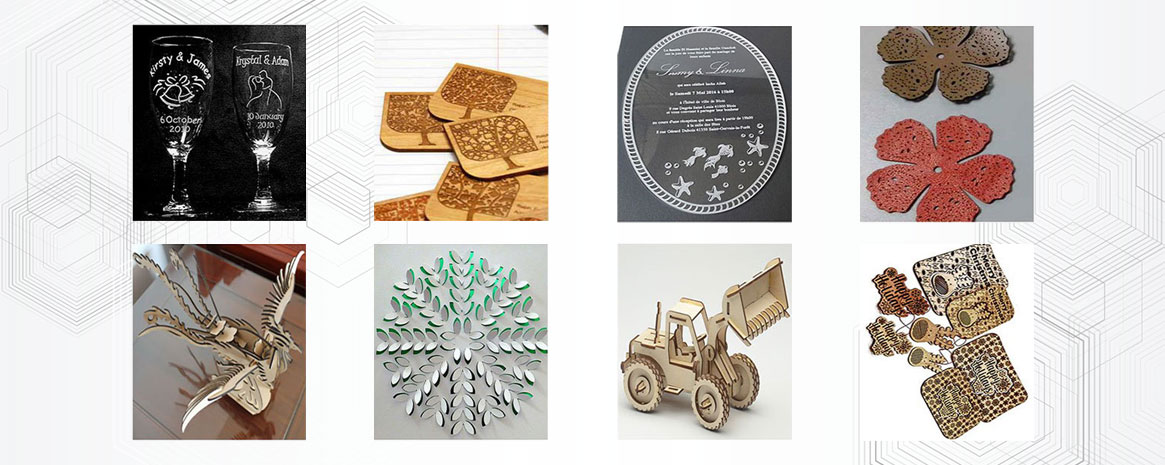

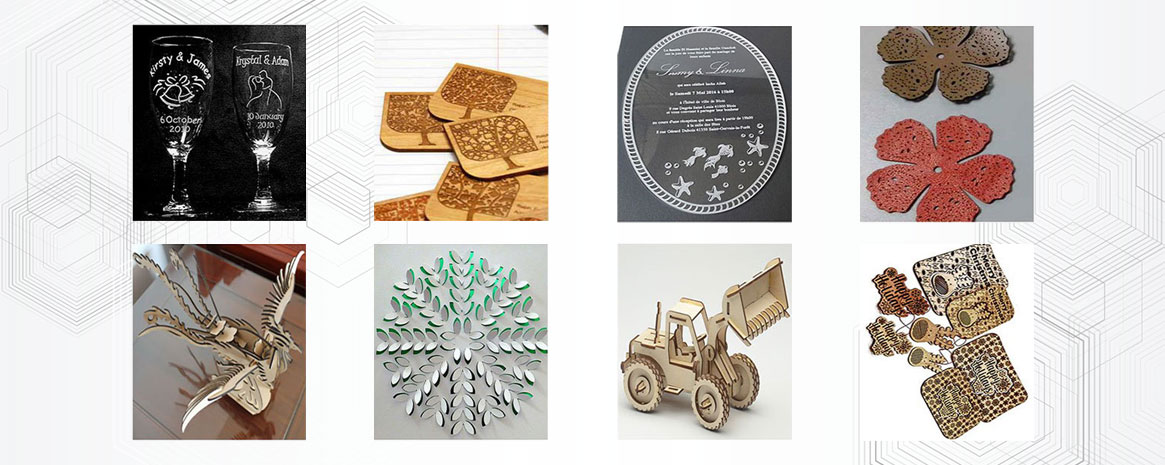

The industrial and commercial value of

co2 laser cutting machine is very good, the scope of application is very wide, and it solves many traditional manual processes to improve work efficiency.

2. The high-energy function of the laser cutting machine produces high temperatures, which will inevitably produce heat, blackening or even burning to the cutting material. For very thin materials, the power can be reduced, but if the product is to be cut, the yellowing will definitely occur. This difficult solution: increase the blowing function, garment

laser cutting machine garment factory uses three-phase stepper motor and driver, laser cutting machine uses water cooling system, the purpose is to reduce the surface temperature of the material at the moment of laser cutting and engraving.

3. For the cut material, secondary processing can be carried out, such as painting doors and windows, so that the yellowing of the cut surface can not be seen, but for paper cutting, if the traditional paper cutting process is used, it must be a physical cutting device. It can meet the requirements of traditional knife carving process. For modern paper-cutting laser cutting, flocking cloth materials and good rice paper are generally selected, such as bamboo pulp paper. Products cut by the surface humidity will be popular in the market. Favor; after all, the craftsmanship made by laser cutting machines is relatively fine.

4. At present, the scope of laser machine equipment is becoming more and more widely used. It is a preliminary intervention state for the paper-cutting industry. It is already a mature machine for the clothing industry. Of course, it is not as efficient as the batch forming efficiency of electric cutter cutting. The laser cutting machine has certain advantages for partial cutting of bags, badges, signs, etc.

Laser cutting and laser engraving applicable fields: electronic and electrical industry, clothing industry, leather industry, furniture industry, decoration industry, craft gift industry, advertising industry, packaging and printing industry, mold industry, cutting, punching, proofing, painting of industrial panels Precision processing fields such as wire.

The application field and application range of laser engraving machine are very broad. Different models have different designs for different industries. ACCTEK specializes in the production of CNC engraving machines and laser machines. If you encounter any problems during the purchase process, you can Feel free to contact our staff, we have a professional team to answer your questions, and hope to help you.