Three-dimensional carving machine is also known as the

four axis engraving machine, three-dimensional carving machine/four axis four linkage engraving machine application range is very wide, even replace the manual carving technology, for the rapid production of large quantities of products laid the foundation.

Three-dimensional carving machine application scope is mainly used for acrylic, VC fabrication, wood, marble, jade and other materials of cutting, 3 d characters, words, designs, relief, the exterior styling, Mosaic, advertising, arts and crafts, badges, non-metallic or copper, aluminum, can make the fine carving on, is the store ads decoration industry indispensable good helper.Now all kinds of floor models are made of realistic original, realistic appearance, smooth lines, high technology content, and fashionable, elegant, suitable for a variety of commercial celebrations souvenirs.

The function of 3d engraving machine is powerful, it can carve out all kinds of complex and beautiful craft products.But now the most important factor that troubles the development of 3d engraving machine is not the cost of the product but the drawing.Engraving machine commonly used THREE-DIMENSIONAL drawing software is 3Ds MAX and PowerMILL, but the existing THREE-DIMENSIONAL modeling software can only generate relatively simple or regular curved shape, a large number of exquisite and complex handicrafts, the method of manual mapping, want to use computer generation and input is still very difficult.

Characteristics

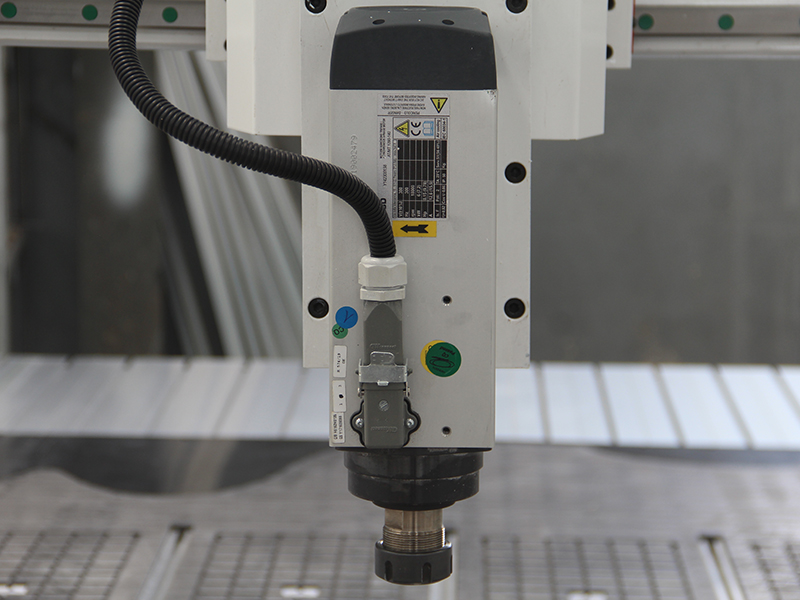

(1) Adopt imported linear circular guide rail, double row and four row ball slider, with large bearing force, stable operation and long life.Original imported ball screw, high precision, precise cutting.

(2) High precision pinion and rack transmission, high speed, high precision.

(3) from the computer, completely equipped with remote operation of USB interface on DSP system, operation lever operation, operating more simple, more humanized design, unique intelligence budget law, give full play to the potential of motor, realize the high speed machining, linear synchronous, the curve is more better, do not take a computer memory, and can implement automatic start-stop cutting spindle.

(4) Strong software compatibility, supporting Type3 /Actcam/Castmate/ Wintai and other CAD/CAM design and production software.

(5) The replaced vacuum adsorption table is equipped with a vacuum pump with strong adsorption capacity. The six-partition design can strongly absorb materials of different areas.

(6) High speed driving stepper motor and driver are adopted, and the Y axis is driven by double motor, which is combined with strong cutting spindle to make the engraving speed faster.

When we use the machine, but do not have too detailed understanding of the engraving machine, there is no technical personnel to give advice, there is no professional testing equipment, is it impossible to compare the performance of which engraving machine?

1, "will use a comfortable" is the most direct way to carving machine capability testing, as the engraving machine the popularization application in various industries, and has become a real batch type professional tools engraving machine, with typical applications in the woodworking industry, for example, home decoration, large plate plane engraving, solid wood, board type furniture, solid wood art murals, real wood door, cabinet door carvings.Craft industry: sewing machine table, electrical counter surface, sporting goods equipment.Musical instrument industry: Engraving musical instrument 3d surface, shape cutting.The main characteristics of the above applications are: the finished products require fine, which requires the equipment capacity and processing technology must have professional characteristics, and can adapt to the batch, so as to obtain better economies of scale.

2. Operators with practical experience know that it is easy to do one job, but it is difficult to do it in batches.This is about to test whether the tool "with the comfortable, comfortable", carving machine is the most significant features are: professional CAD/CAM software and

CNC engraving machine professional and closely, in the use of professional CNC engraving machine for batch processing, professional carving software can ensure that the operator's right to do design, generate reasonable and efficient process.When installed began work material, cutting tool, the operator need to regularly listen to tool cutting sound judgement for wear and replaced when necessary, basically is not accounted for, when processing is complete, if discover some parts processing results do not meet the requirements, the operator use of engraving machine repair function on the scene a little remedy, a batch of live so fluently finished, so work well.

3, low degree of specialization, engraving machine for the operator to design a kind of ideal way of processing, no accident happened in the processing, if the premise is, there is no question of the engraving machine work, but in fact in the batch processing of long time no accident, there is no such thing as this work is "not comfortable".Mainly for the performance of: tool adjustment is difficult to precise positioning and field is difficult to repair the shortcomings in the processing, this is likely to cause: tool positioning accuracy is low, affect the accuracy of finished products, field can not repair must be repeated processing to reduce the processing efficiency.

Engraving machine for precision CNC equipment, necessary daily maintenance and maintenance of the machine life and precision is crucial.

1. After the orientation is determined, it is necessary to put X, Y and axis workpiece coordinates into "0".

2, adjust the carving speed and spindle motor speed, in case of too fast speed, too slow speed and cutting.

3, when taking the initiative to the knife, pay attention to the knife block is necessary to be insulated from the aluminum cutting machine table.

4. When carving, if you are not sure about the first knife or afraid of making a mistake, you can adjust the feeding speed to slow down. If you feel the speed is normal, you can also imitate carving in the air to see if it is normal.

5, if the long time do not use the carpenter carving machine, should be punctual refueling idle every week, it is best for every week, to ensure the flexibility of the transmission system.

6. The continuous operation time shall be less than 10 hours a day to ensure the cleaning of the cooling water and the normal operation of the water pump. It is never allowed to cause water shortage of the water spindle motor.If the working environment temperature is too low in winter, the water in the tank can be replaced by antifreeze.

7. Every time the machine is used, pay attention to cleaning, be sure to clean the dust on the platform and the transmission system, and lubricate the transmission system (X, Y, Z axis) regularly.(Note :X, Y and Z triaxial polished rod shall be maintained with oil;Add high speed butter on the lead screw part;In winter, if the working environment temperature is too low, the part of the lead rod, smooth rod square guide rail or circular guide rail should be cleaned with gasoline first, and then oil should be added, otherwise it will cause too much resistance of the machine transmission part and cause the machine dislocation.

8, the operator had better wear a dust mask and protective glasses when operating the carpenter carving machine, in order to prevent the occurrence of dust during processing into the human body, the formation of discomfort

9, the carpenter carving machine daily protection methods to the carpenter carving machine with certain dust removal equipment, select dust removal equipment matching use.

10. When carrying out maintenance inspection on electrical appliances, the power must be cut off until the display does not show and the main circuit power indicator is off.