With the development of science and technology, advanced technology is constantly applied to various industries, reducing the cost of technology and improving the cost of performance.Engraving machine from research and development to the present use, has been more than 10 years, the technology is also constantly improving.Laser engraving machines use laser instruments to make faster machines.As the core technology of engraving machine NUMERICAL control technology, this technology is to let engraving machine can successfully complete all kinds of gorgeous engraving premise.So how does the CNC engraving machine work?Why is it possible to carve according to a certain pattern?

CNC engraving machine is an automatic machine tool equipped with a program control system, which can make the machine work according to the programmed program.Different kinds of CNC engraving machines have different requirements for sensors. Generally speaking, large machine tools require high speed response, while medium and high-precision CNC machine tools require high accuracy.Of course, in order to make each model of engraving machine can work fast and well, the single numerical control technology update can not meet, the use of laser instruments to engraving machine, this is to make each model of engraving machine work better, precision up, speed is not falling.

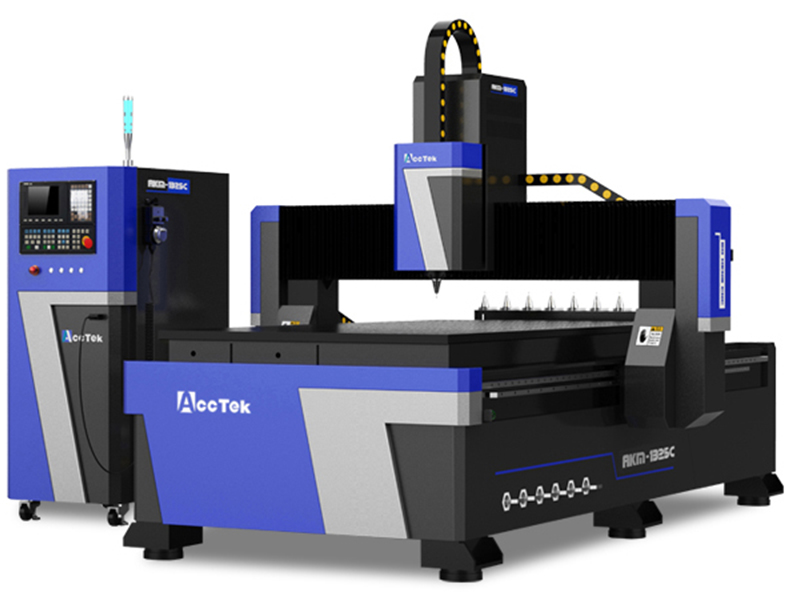

As a result of high precision, high speed, high efficiency and safe and reliable characteristics, in the manufacturing technology equipment update, CNC engraving machine is rapidly gaining popularity in enterprises.It combines the latest technologies in machinery, automation, computers, measurement and microelectronics, using a variety of sensors.CNC engraving machine has the performance, so that some of the original and machine unrelated industries like this machine, so there are a variety of new applications - advertising engraving machine, wood carving machine, stone carving machine, relief, carved materials.

Different types of CNC machine tools on the sensor requirements are not the same, in general, large machine tools require high speed response, medium and high precision CNC machine tools to require precision, of course, with the development of science and technology, this is not necessarily so positioned.Small and medium-sized engraving machine, if the configuration to keep up with, although the price will be a lot higher, but relatively large size engraving machine or cheap, speed and precision are to a certain extent.So, if you want to buy a high-performance advertising engraving machine, you don't have to buy a large size, you can also choose a small model, and then a good configuration engraving machine.

Wood engraving machine in a long time in the process of use there will always be such or such a fault, the driver and water-cooled motor fault should be how to solve?

1, wood engraving machine driver failure

Performance: In the carving process, everything moves normally, but after the machining, the return point at the origin of the workpiece does not coincide with the origin defined at the beginning of the carving process.

Cause: driver failure, replace driver and check whether the supply voltage of driver is normal.

In the process of engraving, especially in the process of high speed machining, there are easy to stop the phenomenon: the driver power supply voltage is not stable;The output current of the driver is too small

Solution: Check whether the power supply voltage is normal, if not, please use the corresponding voltage regulator;Adjust the driver output current,

2, woodworking engraving machine water-cooled motor operation fault

Click "Spindle open:" in the control system, the spindle motor will not rotate

(1)Check the interface of the data cable. If the interface is loose, please reconnect it

(2) Check whether the inverter power supply is normal

(3) Check the LED display screen of the frequency converter for error, refer to the machine debugging, the frequency converter debugging section, the frequency converter parameters to reset.

(4) If the above problems do not exist, then click "Spindle start", check whether the spindle motor start sound, and the spindle can not rotate freely, please check the output end of the frequency converter to the spindle motor line connection part, this problem is the circuit break.

After clicking "Spindle open", the spindle motor will stop running instantly for a period of time and then stop running

(1) Please check the frequency converter to indicate the fault, and the LED to indicate Fu.9 ". This fault is short circuit fault. Check the output port of the frequency converter to the circuit between the main motor and the main shaft to eliminate the short circuit fault.

(2)If the LED screen of the frequency converter prompts "Fu. 1", the fault is the input voltage fault, check whether the input voltage is too high or too low, with the corresponding voltage regulator.

How to choose and buy

woodworking engraving machine carving tools, we need to pay attention to the characteristics of what?Although CNC woodworking engraving machine belongs to the same category of CNC engraving machine, due to the characteristics of its engraving material and processing strength, destined to its machine structure has very high requirements, like the stability of the machine tool, spindle performance and the performance of the tool are very high requirements.Especially carving tool is a big consumable, the customer must choose the tool accurately, otherwise not only affect the carving effect, but also greatly affect the processing quality.

1. High hardness and wear resistance

Hardness is the basic property of tool material. To cut the material from the workpiece, the hardness must be greater than that of the workpiece material.The hardness of tool material is generally above 60HRC.Wear resistance is the ability of the material to resist wear, in general, the higher the hardness of the tool material, the better the wear resistance, the finer the material grain, the more uniform the distribution, the higher the wear resistance.

2. Sufficient strength and toughness

In order to make the tool work under great pressure and under the condition of impact and vibration in the cutting process without breaking edges and breaking, the tool material must have sufficient strength and toughness.

3. High heat resistance

Refers to the hardness, wear resistance, strength and toughness of tool material maintained at high temperature.The higher the high temperature hardness of the tool material, the better the cutting performance of the tool, the higher the allowed cutting speed. In addition to the high temperature hardness, the tool material should also have the ability to resist oxidation and good adhesion and diffusion

4. Good process performance

In order to facilitate manufacturing, the tool material is required to have good process performance.

5. Economy

Economy is one of the important indexes of tool material.Although some tool materials are very expensive, but because of its long life, the cost of apportioning each part is not necessarily high.

6. Predictability of cutting performance

With the development of machining automation, cutter wear and durability are required to be predictable.

Due to the wood engraving machine carved material hardness, material structure and other properties are different, customers in the choice of tools, try to choose according to its specific hardness and processing technology, so that not only can better save processing costs, but also can achieve a better carving effect.