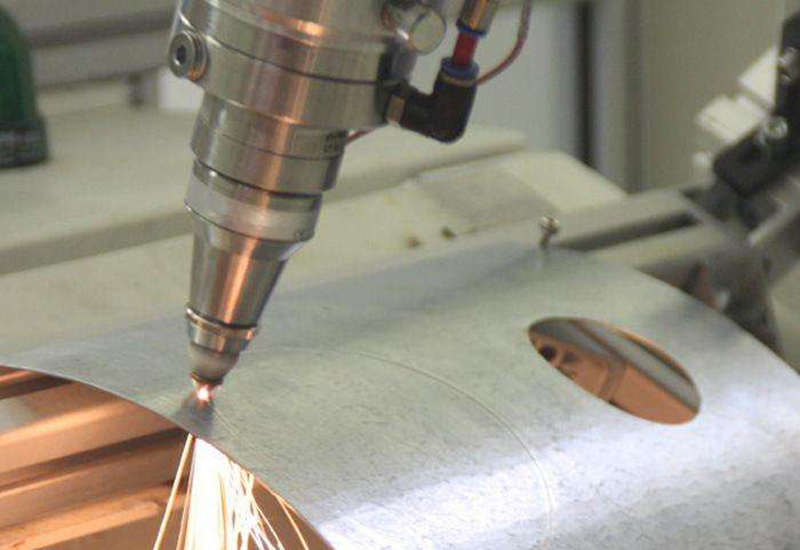

Application of optical fiber Laser machine:

The second parameter is power.What determines your power choice is the thickness of the cut sheet.The thicker the plate, the more difficult cutting, the greater the power required.Ordinary laser cutting machine can also cut carbon steel to 36mm, stainless steel can be up to 25mm.

The advantages of miniaturization and intensification brought by the low manufacturing cost, mature technology and the rao of glass fiber;The glass fiber does not require the same strict phase matching as the crystal for the incident pump light due to the wider absorption band due to the non-uniform broadening caused by the splitting of the glass matrix Stark.Glass material has a very low volume area ratio, fast heat dissipation and low loss, so the up-conversion efficiency is high and the laser threshold is low.The output laser wavelength is more: this is because the energy level of rare earth ions is very rich and there are many kinds of rare earth ions.Tunability: due to the wide rare-earth ion level and the wide fluorescence spectrum of glass fiber.Because there is no optical lens in the resonator of fiber laser, it has the advantages of no regulation, no maintenance and high stability, which is incomparable to the traditional laser.Optical fiber export makes the laser easily qualified for various 3d arbitrary space processing applications and makes the design of mechanical system very simple.Competent for harsh working environment, have high tolerance to dust, shock, shock, humidity and temperature.There is no need for thermoelectric cooling and water cooling, just simple air cooling.

Laser machine selection:

1) The first parameter is the type of light source.The type of light source, namely the type of laser core components of laser cutting machine, generally includes CO2 laser cutting machine, YAG laser cutting machine, fiber laser cutting machine.Each of the three laser cutting machines USES a different material, and your choice is based on the material you want to cut.

2)The second parameter is power.What determines your power choice is the thickness of the cut sheet.The thicker the plate, the more difficult cutting, the greater the power required.Ordinary laser cutting machine can also cut carbon steel to 36mm, stainless steel can be up to 25mm.

3)The third parameter is the cost performance, the current two parameters are basically standard, decide which laser cutting machine, the most important factor is probably the price!But for laser cutting machine this expensive and important equipment, covet the price is cheap, very easy to pay a serious price.A cheap price can mean a discount on quality, or trouble after sales.

The above is all about the laser cutting range. For more information about laser cutter products, please visit the following links:https://www.acctekgroup.com/Laser_Machine/

● Buy a better 5 axis cnc router machine for your shop

● The applicable scope of laser cutting machine

● Application and selection of laser cutting machine

● Principle and technology of laser cutting glass

● How to choose a cnc router

● How to deal with soot in laser cutting and the application field of laser cutting

● Acctek exhibition footprint

● ATC CNC Router with a horizontal spindle

● Polish customer purchased AKM1530 high quality CNC engraving machine

● High quality AKJ1530 CO2 laser cutting machine

Get a Free Quote Now!

Jinan AccTek Machinery Co.,Ltd

Headquarters:3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City

Branch:A3-4-905, Hanyu Jingu, High-tech Zone, Jinan City

Factory:No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province( Postal code 251200)

Email:[email protected]

tel:+086-0531-86160023

video | Knowledge | Events and Support

Copyright © Jinan AccTek Machinery Co.,Ltd 版权所有 Power by DedeCms | XML MAP